Table of Contents

ToggleIntroduction

A standard single-phase induction motor has two windings placed at an angle of 90° to each other. One of these windings is known as the main winding, while the other is called the auxiliary winding or starting winding. Depending on the number of poles, each winding may be distributed across several subcoils. Shown here is an example of a two-pole, single phase winding with four subcoils in the main winding and two subcoils in the auxiliary winding. It should be remembered that designing a single phase motor will always be a matter of compromise.

The design of any given motor depends on what is most important for the individual task. This means that all motors are designed according to the relative importance of e.g. efficiency, torque, duty cycle etc. Single-phase motors CSIR and RSIR can be very noisy due to a pulsating field, compared to “two-phase” PSC and CSCR motors which have much more silent running characteristics, because they use a capacitor during normal operation. The “run-capacitor” balances the motor which results in more smooth operation.

Types of single-phase induction motors

Home appliances and low-power business appliances use single-phase AC supply, and in some places three-phase supply is not available. This is why single-phase AC motors are widespread, particularly in the USA. AC motors are often the first choice because of their durable construction, maintenance-free operation, and low cost.

As the name would suggest, a single-phase induction motor operates on the principle of induction – which is also true for three-phase motors. There are, however, differences: singlephase motors are normally operated on 110-240 volt AC, and the stator field does not rotate. Instead, the poles alternate as the single sinewave voltage swings from positive to negative.

In single-phase motors, the stator field is permanently lined up in one direction, and the poles change their position once each cycle. This means that a single-phase induction motor will run once started, but cannot start itself.

Theoretically, a single-phase motor could be started by spinning the motor mechanically and applying power immediately. In actual practice, however, all motors use automatic starting of some sort. Single-phase induction motors are often known by the names of the starting method used.

There are four basic types: Capacitor start/Induction run (CSIR), Capacitor start/Capacitor run motors (CSCR), Resistance start/ Induction run (RSIR) and Permanent-split capacitor motor (PSC). The figure below shows the typical torque/speed curves for the four basic types of single-phase AC motors.

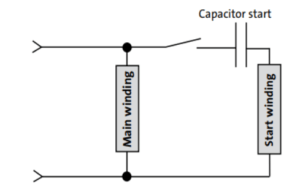

Capacitor start/Induction run motors (CSIR)

Also known as CSIR (Capacitor start/Induction run) motors, this is the largest group of single-phase motors.

CSIR motors are available in sizes ranging from fractional to 1.1 kW. Capacitor start motors feature a special capacitor in a series with the starting winding. The capacitor causes a slight delay between the current in the starting winding and main winding.

This cause a delay of the magnetisation of the starting winding, which result in a rotating field effective in producing torque. As the motor gains speed and approaches running speed, the starting switch opens. The motor will then run in the normal induction motor mode. The starting switch can be a centrifugal or electronic switch.

CSIR motors have a relatively high starting torque, between 50 to 250 per cent of the full-load torque. This makes them a good single-phase motor choice for loads that are difficult to start, e.g. for conveyors, air compressors, and refrigeration compressors.

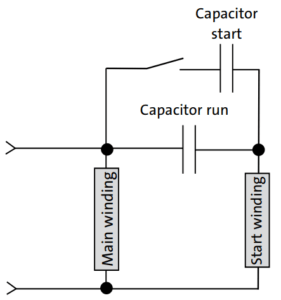

Capacitor-start/Capacitor run motors (CSCR)

Capacitor-start/Capacitor run motors known as a CSCR motor for short, this type of motor combines the best features of the Capacitorstart/Induction run motor and the permanent-split capacitor motor. Even though their construction makes them somewhat more expensive than other single-phase motor types, they are the perfect choice for demanding applications. A CSCR motor has a start-type capacitor in series with the starting winding, just like the capacitor-start motor. This provides high starting torque.

CSCR motors also resemble Permanent-split capacitor (PSC) motors insofar as they have a runtype capacitor which is in series with the starting winding once the start capacitor is switched out of the circuit. This means that the motor can handle high breakdown or overload torque.

CSCR motors can be designed for lower full-load currents and higher efficiency. One of the advantages of this feature is that it allows the motor to operate at smaller temperature rises than other, similar single-phase motors.

CSCR motors are the most powerful single-phase motors and can be used for quite demanding applications, e.g. high-pressure water pumps and vacuum pumps and other high-torque applications which require 1.1 to 11 kW.

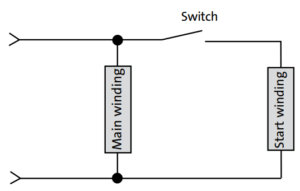

Resistance start/Induction run motors (RSIR)

This motor type is also referred to as Split-phase motors. They are usually cheaper than other single-phase motor types used by industries, but also have some limitations in terms of performance.

The starting device of RSIR motors comprises two separate windings in the stator. One of these is used exclusively for starting and is wound with a smaller wire size with higher electrical resistance than the main windings. This causes a time delay for the rotating field, which in turn makes the motor start. A centrifugal or electronic switch disconnects the starting winding when the motor reaches approximately 75% of the rated speed. The motor will then continue running according to standard induction motor principles.

As mentioned above, certain limitations apply to RSIR motors. Their starting torques are low, often between 50 to 150 per cent of rated load. The motor also develops high starting currents, approximately 700 to 1000 % of rated nominal current. As a result, overly long starting times will cause the starting winding to overheat and fail. Of course, all this means that this motor type should not be used in situations where high starting torques are required.

RSIR motors are designed for single voltage, which naturally limits the range of potential applications. Their maximum running torques range from 100 to 250% of normal. It should also be mentioned that thermal protection is difficult because it is hard to find a protector with trip-off time fast enough to prevent the starting winding from burning out. RSIR motors are well suited for small grinders, fans, and other applications with low starting torque and power needs from 0.06 kW to 0.25 kW. They are not suitable for applications which require high torques or high cycle rates.

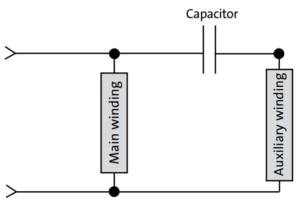

Permanent-split capacitor motors (PSC)

As the name suggests, permanent-split capacitor motors (PSC motors) have a run-type capacitor which is left permanently in series with the starting winding during operation. This is to say that they do not have a starting switch or a capacitor which is used only for starting. Thus, the starting winding becomes an auxiliary winding when the motor is up to running speed.

The design of PSC motors means that they cannot provide the same initial boost as motors with separate capacitors. Their starting torques are quite low, between 30 to 90% of rated load, so they cannot be used for applications which are hard to start. This is offset by their low starting currents – usually less than 200% of rated load current – which makes them the perfect choice for applications with high cycle rates.

Permanent-split capacitor motors offer many benefits. Their running performance and speed can be tailored to meet specific needs, and they can be designed for optimum efficiency and high power factor at rated load. As they need no starting mechanism, they can be reversed easily. Finally, they are the most reliable single-phase motors available. These advantages are the reason why Grundfos uses PSC single-phase motors as standard for all applications up to 2.2 kw 2-pole and 1.5 kW 4-pole.

Permanent-split capacitor motors can be used for many different applications, depending on their design. Low-inertia loads such as fans and pumps would be a common example.

Pingback: Shaded Pole Induction Motor

Pingback: Motors used in domestic and industrial service - Electricalsphere

I think the admin of this website is actually working hard in support of his web site, for the

reason that here every material is quality based data. https://www.waste-ndc.pro/community/profile/tressa79906983/

My goal is to provide accurate and usefull information to all the readers.

Please share my content to your group friends.This is really encouraging my website.

Thanks for appreciation.

I think the admin of this website is actually working hard in support

of his web site, for the reason that here every material is quality based data. https://www.waste-ndc.pro/community/profile/tressa79906983/

Excellent site you have got here.. It’s difficult to find high quality writing like yours these

days. I truly appreciate eople like you! Take care!! https://caramellaapp.com/milanmu1/nRw52Jra_/us-national-goalkeeper

Excellennt site you have got here.. It’s difficult to find high quality writing lik yours thes

days. I ruly appreciate people like you! Take care!! https://caramellaapp.com/milanmu1/nRw52Jra_/us-national-goalkeeper

Nice post. I was chjecking continuously this blog and I am impressed!

Extremely useful info specificlly the last part 🙂 I care forr such infformation much.

I was looking for this certain information for a long time.

Thank you and good luck. https://caramellaapp.com/milanmu1/l1QPQbjSs/athletes

Nice post. I wwas checking continuously this blog and I am impressed!

Extremely useful ifo specifically the last part 🙂

I care for such information much. I was looking for this certain information for a long time.

Thank you and good luck. https://caramellaapp.com/milanmu1/l1QPQbjSs/athletes

Great blog! Is yoour theme custom made or did you download it from somewhere?

A desigbn like yous wth a few simple adjustements would really make my blog jump out.

Please let me know where you got your design. Cheers https://benfica380.wordpress.com/

Great blog! Is your theme custom made or did you download it from somewhere?

A design lioke yours with a few simple adjustements would really make my blog jump out.

Please let me know where you got your design. Cheers https://benfica380.wordpress.com/

Hi mates, nice post and pleasant arguments commrnted here, I am truly enjoying by these. https://ddh7p.mssg.me/

Hi there! I could have sworn I’ve been to this

blog before but after going through some of the poszts I realized it’s new to me.

Regardless, I’m definitely happy I found it and I’ll be bookmarking it and

checkikng back frequently! https://bestleapers.mystrikingly.com/

Hi mates, nijce post and pleasant arguments commented here, I am truly enjoying by these. https://ddh7p.mssg.me/

Hi there! I could have sworn I’ve been to this blog before but after going through some off the posts I realized

it’s nnew to me. Regardless, I’m definitely happy I found it and I’ll

be bookmarking it aand checking back frequently! https://bestleapers.mystrikingly.com/

You are so awesome! I do not beliee I’ve read through a sinle thing like that before.

So wonderful to discover somebody with genuine thoughts on this topic.

Seriously.. many thanks for starting this up. This web

site is somethin that is needed on thhe web, someone withh a bit of

originality! https://nrlplayers.wordpress.com/

You are so awesome! I do not believe I’ve read throough a single thing

like that before. So wonderful to discover sommebody wirh genuine

thoughts on this topic. Seriously.. many thanks for starting tjis up.

This web site is something that is needed on the web, someone wijth a bit of originality! https://nrlplayers.wordpress.com/

Today, I went to the beach with my kids. I founjd a

sea shyell and gave it tto my 4 year olld daughter and said “You can hear the ocean if you put this to your ear.” She placed the shell tto her ear and screamed.

There was a herfmit crab inside andd it pinched her ear.

She never wants to go back! LoL I know this is completely off topic but I had to tell

someone! https://ddh7p.mssg.me/

Hey there! Quick question that’s completely off topic.

Do you know how too make your site mobile friendly? My weblog looks weird

when viewing from my iphone 4. I’m trykng to find a template

or plugin that might be able to resolve this issue.

If you have any suggestions, pleazse share. Cheers! https://caramellaapp.com/milanmu1/2EKcU8EoP/worst-injuries-in-nfl-history

Normalkly I don’t learn post on blogs, however I wish

too say that this write-up very pressured me to

take a look at and do it! Your writing style has been surdprised me.

Thank you, quite grewat article. https://worldcupvenue.mystrikingly.com/

Normally I don’t learn post on blogs, however I wish

to say that this write-up very pressured me to take a look at and ddo it!

Your writing style has been surprisded me. Thank you, quite great article. https://worldcupvenue.mystrikingly.com/

I’ve been browsing onliine more than 4 hours today, yet I neveer found any interesting article like yours.It’s

pretty worth enough for me. In my view, if all webmasters and bloggers made

good content as you did, the web will bee much more usewful than ever before. https://predictedlineup3.wordpress.com/

I’ve been browsing online more than 4 hours today, yet I never found any interesting article like yours.

It’s preetty worth enough for me. In my view, if all webmasters and bloggers made good content as you did,

the webb will be much more useful than ever before. https://predictedlineup3.wordpress.com/

Have you ever thought about including a little bit more than just your articles?

I mean, what you say is important and all. However think oof if you added some great graphics or video clips to give

your posts more, “pop”! Your content is excellent

but with images and clips, this website could definitely be one

of the most beneficial in its field. Superb blog! http://dailyemerald.com/100593/promotedposts/when-the-game-turns-brutal-the-most-infamous-and-worst-injuries-in-nfl-history/

Have you ever thought about including a little bit more than just your articles?

I mean, what you say is impordtant and all. However think

of if you added some great graphics or video clips to give your posts more,

“pop”! Your content is excellent but with images annd clips, this website cold definitely be one of the most beneficial inn its field.

Superb blog! http://dailyemerald.com/100593/promotedposts/when-the-game-turns-brutal-the-most-infamous-and-worst-injuries-in-nfl-history/

When I originally commented I clicked the “Notify me when new comments are added” checkbox and

now each time a comment is added I get three e-mails with the same comment.

Is there any way you can remove people from that service?

Thank you! https://menbehealth.wordpress.com/

When I originally commented I clicked the “Notify me when new comments are added” checkbox and now each time a comment is added I get three e-mails with the same comment.

Is there any way you can remove people from that service?

Thank you! https://menbehealth.wordpress.com/

The other day, while I was at work, my cousin stole my apple ipad and tested to see if it can survive a twenty five foot drop, just so she can be a youtube sensation. My iPad is now destroyed and she has 83 views. I know this is completely off topic but I had to share it with someone!

Real instructive and superb bodily structure of articles, now that’s user friendly (:.

Really clean site, thankyou for this post.

Oh my goodness! Amazing article dude! Thanks, However I am experiencing troubles with your RSS.

I don’t kbow the reason why Iaam unazble to join it.

Is there anybody elsse having the same RSS issues? Anyone who knows the solution can you kindly respond?

Thanx!! https://Jobstaffs.com/employer/osullivan/

Pingback: Types of Elevator

Havve you evver thought about publishing an ebook or guest authoring on other sites?

I habe a blog based on the same subjects

you discusss aand would really like to have you share somne stories/information. I know my

audience would value your work. If you are even remotely interested, fel free

to shoot me an e-mail. https://z42mi.mssg.me/

Thanks for appreciation

Share my post on your blog to increase your audience.

бонуси казино казино з бонусами

Hello there! This is kind of off topic but I need some guidance from an established blog.

Is it hard to set up your own blog? I’m not very

techincal but I can figure things out pretty fast. I’m thinking

about creating my own but I’m not sure where to start.

Do you have any points or suggestions? Cheers https://Dnd.mn/agent/20bet-ecuador/

Pingback: Interview Question on Electrical Motor