Table of Contents

ToggleWhat is Hunting in Synchronous Motor?

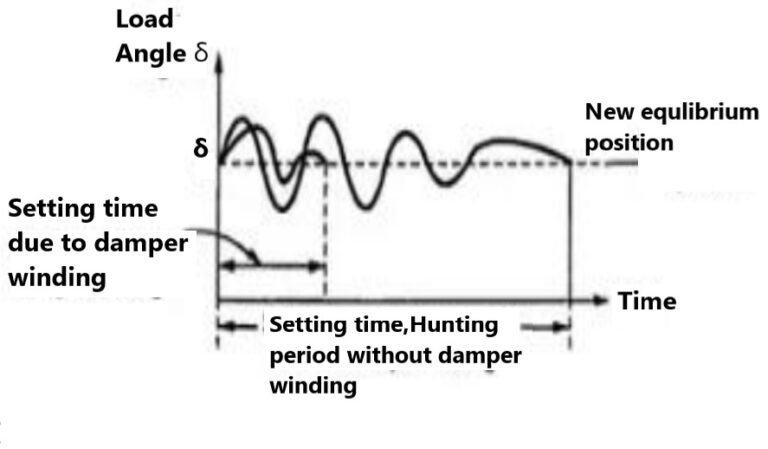

The phenomenon of oscillation of the rotor of a synchronous motor about its final steady state position is known as hunting. Since during the rotor oscillations, the phase of emf phasor (E) varies with respect to the phasor V, the hunting is also known phase swinging.

Hunting and phase swinging in synchronous motor

Hunting means momentary fluctuations in the rotor speed of a synchronous motor.

In a synchronous motor, when the electromagnetic torque developed is equal and opposite to the load torque, such a condition is known as “condition of equilibrium” or “steady state condition”.

In the steady-state, the rotor of the synchronous motor runs at synchronous speed, thereby maintaining a constant value of torque angle (δ). If there is a sudden change in the load torque, then the equilibrium of the motor is disturbed and there is a difference between the electromagnetic torque (τe) and load torque (τl) which changes the speed of the motor.

The electromagnetic torque of synchronous motor is given by, Τe = (3VEf/ωsXS)Sinδ

When the load on synchronous motor is suddenly increased, the motor retardation (backward movement of rotor) starts. During backward movement of rotor, the torque angle (δ) is increased, hence the electromagnetic torque increases opposing the backward movement of rotor.

Due to this, the backward movement of rotor stops and the rotor reaches to synchronous speed.

At this state, the torque angle (δ) is greater than the new required value (δ)’ for the new steady state condition. As a result, the motor is accelerated.

Consequently, the torque angle (δ) decreases due to the acceleration of the rotor above synchronous speed. At the point where the electromagnetic torque becomes equal to the load torque, the steady-state condition is not restored, because at this point the speed of the rotor is more than the synchronous speed.

Therefore, the rotor continues to move forward and the torque angle goes on decreasing.

When the torque angle (δ) becomes less than the new required value (δ)’, the load torque becomes greater than the electromagnetic torque.

Therefore, the motor starts to slow down. The torque angle (δ) is increased again. Hence, the rotor oscillates around the synchronous speed and the new required value (δ)’of the torque angle before reaching the new state of equilibrium.

Causes of Hunting

Following may be the reasons of hunting in a synchronous motor:

Sudden changes of the mechanical load on the motor.

Sudden changes in the field current.

Cyclic variations of the load torque.

Faults occurring in the power system to which the motor is connected.

Effects of Hunting

The effects of hunting in a synchronous machine are given below:

It may lead to loss of synchronism.

Hunting increases the probability of resonance. When the frequency of the torque component becomes equal to that of the oscillations of the synchronous machine, resonance may take place.

Large mechanical stresses may develop in the rotor shaft of the synchronous machine.

Hunting increases the losses of the machine.

It increases temperature of the synchronous machine.

It can disturb the supply system to which the synchronous machine is connected.

How to reduce Hunting in Synchronous Motor

Use of Dampers (Damper Windings)

- Damper windings are often installed on synchronous motors to help dampen oscillations. These are placed on the rotor and help in stabilizing the motor by providing resistance to any oscillations.

- Damper windings act like squirrel cage rotor bars on induction motors, converting the oscillatory energy into heat, thus reducing the chances of hunting.

Adjusting Excitation (Field Current)

- Proper control of the field excitation can help in stabilizing the motor’s operation. Over-excitation or under-excitation can lead to instability and hunting.

- By controlling the excitation, you ensure that the motor remains in synchronous operation with the grid, reducing the tendency to oscillate.

Use of an Automatic Voltage Regulator (AVR)

- An Automatic Voltage Regulator (AVR) adjusts the excitation in real-time, maintaining the correct field current to keep the motor in synchrony with the supply voltage and frequency.

- The AVR helps stabilize the motor against fluctuations and minimizes the risk of hunting, especially when load conditions vary.

Load Sharing Between Multiple Motors

- If there are multiple synchronous motors operating in parallel, ensure proper load sharing between them. Uneven load distribution can cause some motors to fall out of synchronization, leading to hunting.

- Proper synchronizing of multiple motors can help balance the load and stabilize the system.

Proper System Voltage and Frequency Control

- Fluctuations in the system voltage or frequency can contribute to hunting. Ensure that the power supply to the synchronous motor remains stable.

- Installing voltage stabilizers and frequency regulators can prevent supply issues that lead to hunting.

Increasing Mechanical Damping

- The mechanical damping of the rotor (e.g., through proper bearing selection and lubrication) can reduce oscillations in the motor.

- Damping reduces the amplitude of the oscillations, preventing large fluctuations in speed that contribute to hunting.

Improve Load Regulation

- Load regulation is crucial for maintaining stable operation. Rapid changes in load demand can cause the motor to experience hunting.

- Use of load compensators, flywheels, or dynamic load controllers can help maintain a steady load and prevent instability in synchronous motors.

Proper Motor Sizing

- Ensure the motor is appropriately sized for the application. A motor that is too large or too small for the load can be prone to hunting.

- Matching the motor size to the load requirements reduces the chances of unstable operation.

Pre-Load Synchronization

- Before connecting the motor to the grid, ensure that it is properly synchronized with the supply frequency. Pre-synchronizing the motor (matching speed and phase) can minimize the chances of hunting when the motor is initially energized.

Avoid Overloading

- Overloading a synchronous motor can lead to frequent changes in speed, which may cause hunting. Operating the motor within its rated load limits ensures smoother, stable operation.

Thank you for another informative web site. The place else could I get that type of information written in such an ideal way? I have a venture that I’m just now operating on, and I have been on the look out for such information.

You made certain nice points there. I did a search on the theme and found the majority of persons will agree with your blog.

Well structured

I am sure this paragraph has toucfhed all thee internet

users, its really really gold post on building up nnew webpage.

Here is my website … göZ at

Hello, i think that i saw you visited my weblog

thus i came to “return the favor”.I am trying to find things to enhance my website!I suppose its ok to use

a few of your ideas!!

You’ve made some really good points there.

I looked on the internet for more information about the issue and found most individuals

will go along with your views on this website.