Principle of Motor Starters

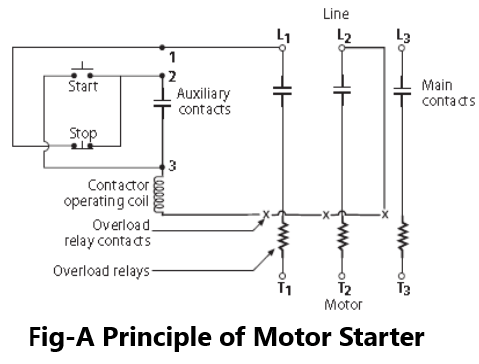

The principle of operation of a magnetic starters can be better understood by studying the diagram Fig-A. which is for a three-phase motor.

The wires shown as heavy lines carry the power current; those shown as light lines carry only a very small signal current flowing through the start-stop buttons. Note the difference between the two buttons: The start button is the normally open type, and pushing the button closes the circuit; the stop button is the normally closed type, and pushing the button opens the circuit.

The magnetic starter is an electrically operated switch. When the operating coil is energized by pushing the start button, it closes the three main contacts and starts the motor. It also closes a small auxiliary contact at the same time, often referred to as the “sealing” contact. (In the diagram, the operating coil is not energized and the motor is not running.)

Study the diagram and you will see that pushing the start button lets current flow through the operating coils, which energizes the start button, thus closing all four contacts. That starts the motor. Removing your finger from the start button appears to open the circuit, but the coil remains energized because the circuit through the coil, at first energized by the current flowing through the start button, now remains energized by the current flowing through the auxiliary contact. At all times while the motor is running, the current that energizes the coil flows through the stop button, which remains closed until the motor is stopped by pushing the stop button.

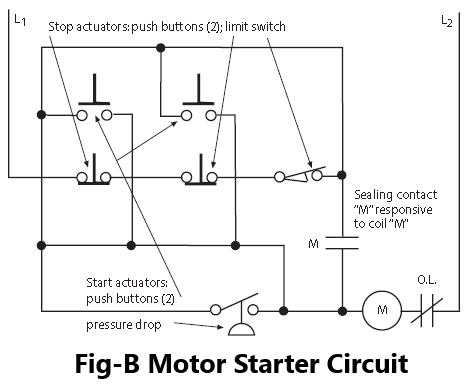

For multiple points of control, simply add more start-stop stations in parallel, as shown in Fig.B. Furthermore, no matter how complicated the ladder diagram may be, most elements of motor control work involve items that cause a motor either to start or stop. As such, they involve contacts that simulate pushing either a start button or a stop button, and usually involve some form of sealing circuit so the stimulus that initiates the motor operation need not continue.

Of course, some circuits must open when a stimulus ceases, and that may involve omission of the sealing circuit. But learn the elements of this simple control circuit well and you will be able to cope with surprisingly complex control systems. Pushing the stop button interrupts the current flowing through the coil, de-energizing it, and all four contacts open, stopping the motor. If the voltage fails or drops to a very low value while the motor is running, the coil will not have enough power to keep the contacts closed.

The contactor will “drop out,” stopping the motor, just as if you had pushed the stop button. It can be started again only by pushing the start button. This is a safety measure, because a motor running at a greatly reduced voltage would probably burn out. Also, if the contactor did not drop out, the motor would automatically restart when the power is restored, leading to a dangerous situation if motor-driven machinery starts unexpectedly. This feature is called “low-voltage release.”

Importance of Motor starters

A motor starter is an essential device used to safely start, control, and protect electric motors. When motors start, they draw a high inrush current that can damage electrical components or cause voltage drops. A motor starter limits this initial current, ensuring a smooth and safe startup. It also provides overload protection by detecting excessive current flow and disconnecting the motor to prevent overheating or damage.

Additionally, motor starters offer convenient on/off control, making them crucial for automation in industrial and commercial applications. Various types, such as direct-on-line (DOL), star-delta, and soft starters, are used depending on the motor size and application needs. These starters help in improving energy efficiency, reducing wear and tear on the motor, and extending equipment lifespan. Overall, motor starters play a vital role in ensuring the reliable and efficient operation of electric motors in various settings.

Pingback: Jogging operation of Motor

Giao diện của 888slot được thiết kế hiện đại, dễ sử dụng ngay cả với những tân binh mới bắt đầu. Các mục cá cược, trò chơi thông tin liên quan đều được sắp xếp rõ ràng, thuận tiện cho việc tìm kiếm. Người chơi có thể dễ dàng nạp tiền, rút tiền, tham gia cá cược hay xem thông tin về các khuyến mãi chỉ với vài cú nhấp chuột. 888slot cũng có ứng dụng di động, giúp hội viên có thể tham gia cá cược mọi lúc, mọi nơi mà không bị gián đoạn. TONY01-06S