Table of Contents

ToggleIntroduction

The accelerated depletion of fossil fuels, increasing power demands, and harmful consequences of fossil fuels on the environment are resulting in the crucial need for the usage of alternate energy resources. An energy storage system is the ability of a system to store energy using the likes of electro-chemical solutions.

Solar energy and wind energy are the top projects the world is embarking on as they can meet future energy requirements, but because they are weather dependent it is necessary to store the energy generated from these sources [9]. Energy storage systems absorb the excessive energy when generation exceeds predicted levels and supply it back to the grid when generation levels fall short.

Electric Storage technologies can be utilized for storing excess power, meeting peak power demands and enhance the efficiency of the country’s power system ; these technologies include electrochemical, water electrolysis, compressed air, flywheels and superconducting magnetic energy storage. Battery energy storage systems (BESS) are a sub-set of energy storage systems that utilize electrochemical solutions, to transform the stored chemical energy into the needed electric energy.

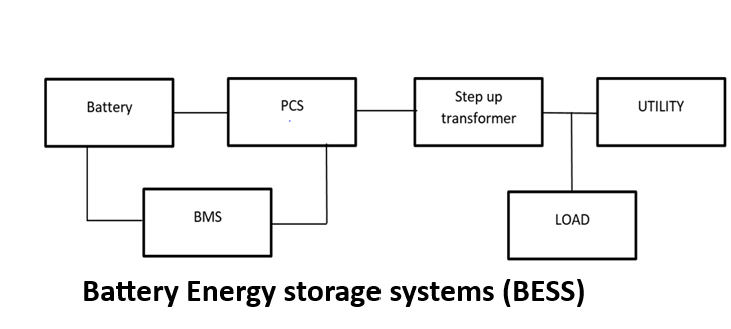

A BESS is of three main parts; batteries, inverter-based power conversion system (PCS) and a Control unit called battery management system (BMS). Figure presents the block diagram structure of BESS.

Battery systems are made of different types of rechargeable secondary batteries; batteries that can be charged. The following sub-sections discuss the main features of various types of batteries.

Lead Acid

These are the oldest and evolved batteries. They consist of a sponge metallic lead anode, a lead dioxide cathode and a sulfuric acid solution electrolyte. They have numerous favourable traits such as relatively affordable, simplicity of manufacturing thereof, and acceptable life cycle under measured conditions , with a major drawback of using a heavy metal component that makes them harmful to the environment. Due to the high cost associated with them, the limited life-span and low energy density, these batteries are not advantageous for the large-scale applications.

Sodium Sulphur (NaS)

They are regarded as the most advanced high-temperature batteries, even though they are relatively new in power system applications . Made of active materials of molten sodium and molten Sulphur, separated by a solid beta alumina ceramic electrolyte. They are favourable to use in relatively large-scale BES applications; due to their inexpensive materials, exceptional high energy density, high-efficiency charge/discharge rate, zero maintenance, and long-life specifications .

However, there are a few large-scale application restrictions, such as high-temperature condition that require to maintain Sulphur in its molten form addressed as a small threat to the operators and environment . The system must constantly be monitored, to prevent the reaction with the atmosphere, because the interaction of pure sodium with air will result in a disastrous explosion instantly.

Lithium- ion (Li-ion)

These batteries are composed from lithium metal or lithium compounds as an anode. They comprise of advantageous traits such as being lightweight, safety, abundancy and affordable material of the negatively charged electrode “cathode” making them an exciting technology to explore .

Li-ion batteries offer higher charge densities and have a minimum environmental impact as the lithium oxides can be recycled. They can provide the much-needed power by the network instantaneously due to the response time that’s in the order of milliseconds.

Li-ion batteries are highly reassuring for large grid-scale applications due to their ability to decrease outage costs and desirable functionalities such as providing a high-power capacity, low self discharge and the highest efficiency. The major disadvantages are that they have capacity loss over time and their ageing is accelerated by high operating temperature.

Control methods to charge/discharge BESS

The BESS is operational in two modes; the discharging mode to alleviate the utility when the distribution network is down or during the peak-load period time and charging mode to fill the battery bank during an off-peak period or when the network gets restored. Possible ways to discharge the BESS , with the assumption the batteries are fully charged are:

Time based control with constant discharge rate

Time-Temperature based control with stable discharge

Time-Temperature Control with variable discharge

Power or Voltage control

Radio-Control (part of SCADA system)

Battery management system (BMS) is an efficient control for the power conversion systems (PCS) in both the charge and discharge storage modes, that is designed for the distribution system operations. The PCS with the help of BMS can supply back-up power with a low distortion AC voltage to the distribution loads via the point of common interconnection via a breaker. The main Control features of PCSs to consider are:

Active/Reactive power control

The PCSs provide both active and reactive power control functions. When the active/reactive command value exceeds the rated value, active power output takes priority over reactive power. PCS controls the charge/discharge flow of the battery bank as required according to the active/reactive power command from the remote SCADA system.

Grid Interaction features

Grid regulations for distribution systems have critical requirements on control functions of PCS, such as low voltage ride-through (LVRT), and the control functions are stored in the control circuit of PCS. The auto-restart function is one of those included in the control circuit, to ensure that the PCS can disconnect from the grid automatically when a grid fault is detected, and also enable for the PCS to restart and reconnect to the grid automatically when the fault is cleared.

Stand-alone operation

When the grid fails, the PCS can switch to stand-alone operation to supply the network loads independently, and when the grid recovers the PCS can switch back to normal operation mode to charge/discharge. The PCS provides the rated AC voltage at the rated frequency to load.