Table of Contents

ToggleIntroduction of DC Machines

The DC machine can be classified into two types namely DC motors as well as DC generators. Most of the DC machines are equivalent to AC machines because they include AC currents as well as AC voltages in them.

The output of the DC machine is DC output because they convert AC voltage to DC voltage. The conversion of this mechanism is known as the commutator, thus these machines are also named as commutating machines. DC machine is most frequently used for a motor.

The main benefits of this machine include torque regulation as well as easy speed. The applications of the DC machine are limited to trains, mills, and mines. As examples, underground subway cars, as well as trolleys, may utilize DC motors. In the past, automobiles were designed with DC dynamos for charging their batteries.

Working Principle of DC Machines

A DC machine is an electromechanical energy alteration device. The working principle of a DC machine is when electric current flows through a coil within a magnetic field, and then the magnetic force generates a torque which rotates the dc motor.

The DC machines are classified into two types such as DC generator as well as DC motor. The main function of the DC generator is to convert mechanical power to DC electrical power, whereas a DC motor converts DC power to mechanical power.

The AC motor is frequently used in the industrial applications for altering electrical energy to mechanical energy. However, a DC motor is applicable where the good speed regulation & ample range of speeds are necessary like in electric-transaction systems.

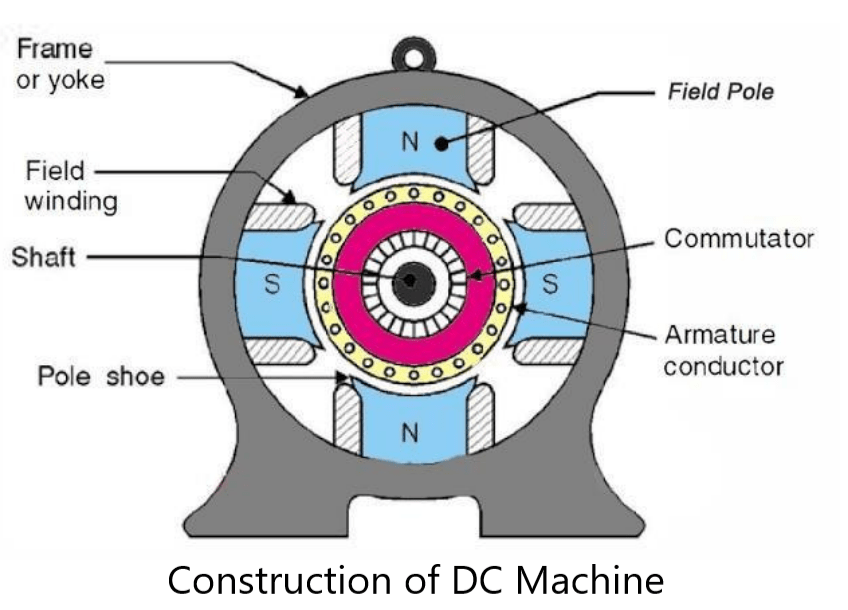

Construction of DC Machine

The construction of DC machine can be done using some of the essential parts like Yoke, Pole core & pole shoes, Pole coil & field coil, Armature core, Armature winding otherwise conductor, commutator, brushes & bearings. Some of the parts of the DC machine is discussed below.

Yoke

Another name of a yoke is the frame. The main function of the yoke in the machine is to offer mechanical support intended for poles and protects the entire machine from the moisture, dust, etc. The materials used in the yoke are designed with cast iron, cast steel otherwise rolled steel.

Pole and Pole Core

The pole of the DC machine is an electromagnet and the field winding is winding among pole. Whenever field winding is energized then the pole gives magnetic flux. The materials used for this are cast steel, cast iron otherwise pole core. It can be built with the annealed steel lamination for reducing the power drop because of the eddy currents.

Pole shoe

Pole shoe in DC machine is an extensive part as well as enlarge the region of the pole. Because of this region, flux can be spread out within the air-gap as well as extra flux can be passed through the air space toward armature. The materials used to build pole shoe is cast iron otherwise cast steed, and also used annealed steel lamination to reduce the loss of power because of eddy currents.

Field winding

In this, the winding are wounded in the region of pole core & named as field coil. Whenever current is supplied through field winding then it electromagnetic the poles which generate required flux. The material used for field winding is copper.

Armature core

Armature core includes the huge number of slots within its edge. Armature conductor is located in these slots. It provides the low-reluctance path toward the flux generated with field winding. The materials used in this core are permeability lowreluctance materials like iron otherwise cast. The lamination is used to decrease the loss because of the eddy current.

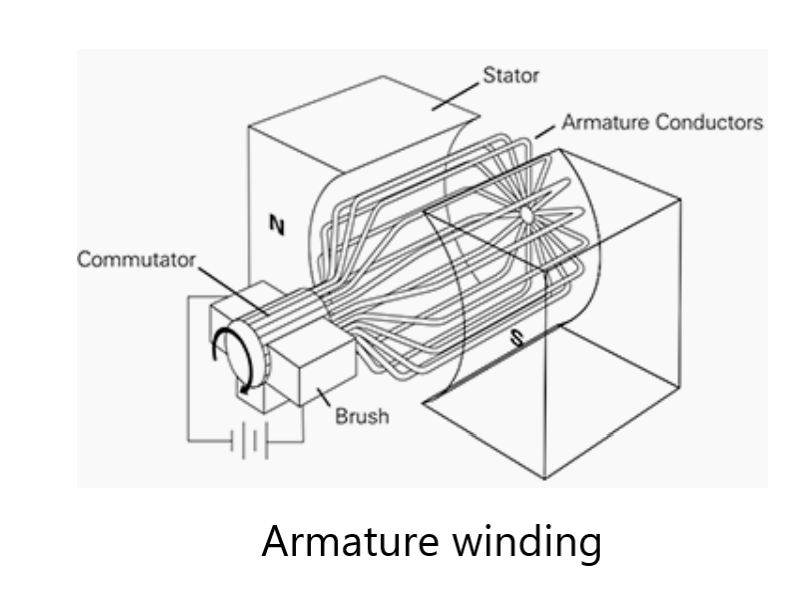

Armature winding

The armature winding can be formed by interconnecting the armature conductor. Whenever an armature winding is turned with the help of prime mover then the voltage, as well as magnetic flux, gets induced within it. This winding is allied to an exterior circuit. The materials used for this winding are conducting material like copper.

Commutator

The main function of the commutator in the DC machine is to collect the current from the armature conductor as well as supplies the current to the load using brushes. And also provides uni-directional torque for DC-motor. The commutator can be built with a huge number of segments in the edge form of hard drawn copper. The Segments in the commutator are protected from thin mica layer.

Brushes

Brushes in the DC machine gather the current from commutator and supplies it to exterior load. Brushes wear with time to inspect frequently. The materials used in brushes are graphite otherwise carbon which is in rectangular form.

Types of DC Machines

The excitation of the DC machine is classified into two types namely separate excitation, as well as self-excitation. In separate excitation type of dc machine, the field coils are activated with a separate DC source. In self-excitation type of dc machine, the flow of current throughout the field-winding is supplied with the machine. The principal kinds of DC machine are classified into four types which include the following.

Separately excited DC machine, Shunt wound/shunt machine, Series wound/series machine, Compound wound / compound machine

Application of DC Machines

DC Motors used in conveyor belts, elevators, cranes, and other industrial applications where variable speed and torque control are required. In older vehicles, DC motors were used in windshield wipers, power windows, and electric seats.

DC motor used in household appliances like vacuum cleaners, mixers, and electric razors.Used in power tools like drills and grinders.

DC Generator used in small, portable generators for providing DC power in remote locations or during power outages. In older vehicles, DC generators were used to charge the battery and power electrical systems.

DC machines are used in battery chargers for charging lead-acid batteries in automotive and industrial applications.

DC motors are used in various speed control applications, such as in conveyor belts and fans and also use in precise positioning is required, such as in robotics and CNC machines.

Used in electric vehicles for propulsion, such as electric cars, trains, and trams, boats and ships for propulsion and other electrical systems.

Pingback: What is Power factor and their calculation formula - Electricalsphere

Pingback: What is Back EMF in DC Motor and their Significance - Electricalsphere

Pingback: Why Dc series motor is never started without load

I absolutely loved checking out this piece! Your information are perfect and extremely useful for those of us in the construction industry.

It’s always a pleasure to come across in-depth articles that speaks directly

to the challenges we deal with today. I’ll be referencing this on my website about home construction, as I am sure my

followers will enjoy it as much as I did.

Great job and thanks for posting!

Pingback: Three-point starter method of DC Motor - Electricalsphere

Pingback: Types of Railway Track Electrification - Electricalsphere

Pingback: Electric Drive: Block diagram and Advantages

Pingback: Interview question on DC Machine - Electricalsphere

It’s perfect time to make some plans for the future and it’s time to be happy. I have read this post and if I could I want to suggest you few interesting things or suggestions. Maybe you could write next articles referring to this article. I want to read even more things about it!