Table of Contents

ToggleComponents of Electric Car

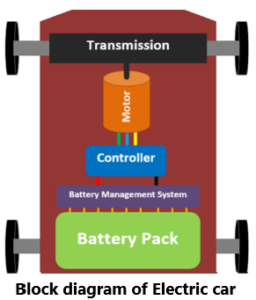

Battery Pack: Batteries are the fuel source for Electric Cars. The voltage rating of the cells (per cell) will be anywhere from 3.7V for a lithium battery and a maximum of 12V for Lead Acid batteries. But as you might have guessed this voltage is not enough to run an electric car. The Tesla for example has a battery pack voltage of 356 Voltas and even for a normal electric bi-cycle we need a minimum of 36V so how do we get this higher voltage from lithium cells that are only 3.7V. So, to get the higher voltage from 3.7V lithium cells, battery packs are used which are formed by combining more than one battery together.

When two batteries are connected in series their voltage ratings are added and when two batteries are connected in parallel their Ah rating is added. For example, assume we have 3.7V 2000mAh Lithium batteries. If you connect two of these in series the resulting system is called a module and this module will have 7.4V 2000mAh. Likewise, if we connect two of these in parallel the resulting module will be 3.7V 4000mAh.monitored for a safe operation.

Battery Management System (BMS) Controller: Once the system Voltage and Ampere hour (Ah) rating is obtained by combining various modules in series and parallel configuration this set-up should be placed inside the EV. But it is not so easy; the reason is -its complexity. Lithium cells are unstable in nature and any mishap like short circuit or excess charging or discharging can make there batteries get very hot leading to fire or explosion.

So, the voltage, current and temperature of each cell should be The duty of monitoring the cells during the charging and discharging procedure is given to the circuit called Battery Management system or BMS for short. Every BMS measures only three vital parameters of the battery which are the Voltage, current and Temperate of the cell. It constantly compares these values with safety limits and disconnects the load if they exceed the threshold values.

Apart from safety purpose the BMS is also used for some computational purpose like measuring the parameters of a battery. So, once the battery modulus is ready it should be connected to the BMS and a cooling system for safe operation of battery. The complete set-up is kept in a steel casing to prevent mechanical damage. This complete arrangement along with the BMS, cooling system casing and the battery modules all together is called as a Battery Pack of a car.

Motor: – There are many types of Motors used in EV and the one used for Scooters and bikes is totally different form the one that is used in cars. The commonly used ones that are BLDC motors, Brushed DC motors and AC Induction Motor.

a) BLDC Motors: BLDC Motors have been the choice for EV’s from its origin in 1900. Even today it is commonly used in Electric cycles and scooters. BLDC stands for Brush Less DC motor; these motors have a constant torque and fast response making it suitable for automotive applications. Apart from EV’s these motors are also used in wipers, power windows etc.

b) Brushed DC motors: The Brushed DC motor also known as DC series motor was the preferable choice for all old Electric cars. These motors provide a lot of torque which could easily give a sporty feel to the EV. The pull/pick-up of the EV would be almost at par with an average conventional car that these motors were used by drag racers during then. But now after 2008, these motors are not much in use any longer the reason is DC motors cannot provide a constant torque under a varying load. Meaning cursing or climbing a hill with the car will be difficult. Also, DC motors cannot start without a load that is it cannot self start due to its high initial current which might damage the motor itself.

c) AC Induction Motors: Most Modern-day Electric cars like the Tesla uses an AC Induction motor. The reason why these motors are selected is that they do not have permanent magnets within them and thus low cost. It also has good life since there are no magnets, magnets would lose their tendency in day course. The downside of the motor would be that it is hard to control the speed and torque of the motor and advanced circuitries are required.

Transmission unit: All cars have gears, including electric cars. However most electric cars do not have nor need a multispeed transmission due to the high torque available over a very wide range of motor speeds. Generally, the electric motor is always connected to the drive wheels through a fixed ratio reduction gear.

Types of electric car

There are three types of electric vehicle: Battery Electric Vehicle (BEV), Plug in Hybrid Electric Vehicle (PHEV) and Hybrid Electric Vehicle (HEV).

- Battery electric vehicle (BEV): These runs entirely using an electric motor and battery, without the support of a traditional internal combustion engine, and must be plugged into an external source of electricity to recharge its battery. Like all electric vehicles, BEVs can also recharge their batteries through a process known as regenerative braking, which uses the vehicle’s electric motor to assist in slowing the vehicle, and to recover some of the energy normally converted to heat by the brakes. Most have ranges of 80 to 100 miles, while a few luxury models have ranges up to 250 miles. When the battery is depleted, it can take from 30 minutes (with fast charging) up to nearly a full day (with Level 1 charging) to recharge it, depending on the type of charger and battery.

Advantages: 1. No emissions 2. No gas or oil changes 3. Ability to conveniently charge at home 4. Fast and smooth acceleration 5. Low cost of operation – about $30 a month.

Disadvantages: 1. Shorter range than gasoline vehicles, although most people drive well within the range of today’s BEV and could rent a hybrid for the rare long trips. 2. Slightly more expensive than their gasoline equivalent although the gasoline savings pay off the difference in typically 2-3 years.

2) Plug-in Hybrid Electric Vehicle (PHEV) Plug-in hybrids (PHEVs) use an electric motor and battery that can be plugged into the power grid to charge the battery, but also has the support of an internal combustion engine that may be used to recharge the vehicle’s battery and/or to replace the electric motor when the battery is low. Because Plug-in Hybrids use electricity from the power grid, they often realize more savings in fuel costs than tradition hybrids electric vehicles (HEV).

Advantages: 1. Longer range than BEV 2. Less gas consumption than gas only vehicle 3. Fewer emissions 4. Very simple mechanics, less to go wrong.

Disadvantages: 1. Produces tailpipe emissions 2. Needs gas and oil changes 3. More expensive to operate than Battery Electric Vehicle (BEV) but less than traditional.

3) Hybrid Electric Vehicle: Hybrid Electric Vehicles (HEVs) have two complementary drive systems: a gasoline engine with a fuel tank; and an electric motor with a battery. Both the engine and the electric motor can turn the transmission at the same time, and the transmission then turns the wheels. HEVs cannot be recharged from the electricity grid – all their energy comes from gasoline and from regenerative braking.

Advantages: 1. Longer range than BEV 2. Less gas consumption than gas only vehicle 3. Fewer emissions than gas only vehicle

Disadvantages: 1. Still produces emissions 2. Complex mechanics – Gasoline + Electric 3. Expensive to operate (8-10 times more expensive than BEV) but less than traditional gasoline vehicle. 4. No ability to conveniently charge at home.

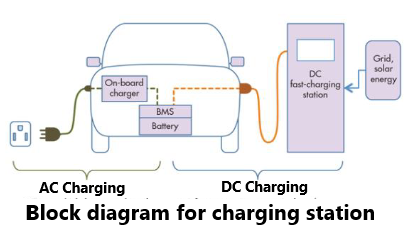

Charging Stations for Electric car

Residential charging stations: An EV owner plugs into a standard when he or she returns home, and the car recharges overnight. A home charging station usually has no user authentication, no metering, and may require wiring a dedicated circuit. Some portable chargers can also be wall mounted as charging stations

Charging while parked: A commercial venture for a fee or free, offered in partnership with the owners of the parking lot. This charging may be slow or high speed and encourages EV owners to recharge their cars while they take advantage of nearby facilities. It can include parking stations, parking at malls, small centers, and train stations (or for a business’s own employees).

Fast charging at public charging stations: These have rating more than 40 kW, capable of delivering over 60-mile (97 km) of range in 10–30 minutes. These chargers may be at rest stops to allow for longer distance trips. They may also be used regularly by commuters in metropolitan areas, and for charging while parked for shorter or longer periods.

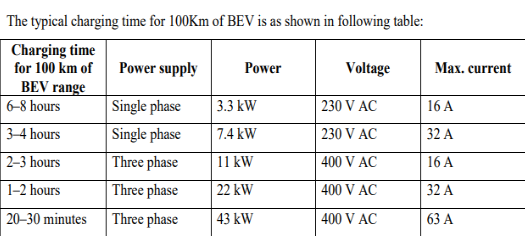

Charging Time of Electric Car

Fuel cell for Electric car

Polymer exchange membrane fuel cell (PEMFC): The PEMFC has a high power density and a relatively low operating temperature (ranging from 60 to 80 degrees Celsius, or 140 to 176 degrees Fahrenheit). The low operating temperature means that it doesn’t take very long for the fuel cell to warm up and begin generating electricity. We will take a closer look at the PEMFC in the next section.

These fuel cells are best suited for large-scale stationary power generators that could provide electricity for factories or towns. This type of fuel cell operates at very high temperatures (between 700 and 1,000 degrees Celsius). This high temperature makes reliability a problem, because parts of the fuel cell can break down after cycling on and off repeatedly. However, solid oxide fuel cells are very stable when in continuous use.

In fact, the SOFC has demonstrated the longest operating life of any fuel cell under certain operating conditions. The high temperature also has an advantage: the steam produced by the fuel cell can be channeled into turbines to generate more electricity. This process is called co-generation of heat and power (CHP) and it improves the overall efficiency of the system.

Alkaline fuel cell (AFC): This is one of the oldest designs for fuel cells; the United States space program has used them since the 1960s. The AFC is very susceptible to contamination, so it requires pure hydrogen and oxygen. It is also very expensive, so this type of fuel cell is unlikely to be commercialized.

Molten-carbonate fuel cell (MCFC): Like the SOFC, these fuel cells are also best suited for large stationary power generators. They operate at 600 degrees Celsius, so they can generate steam that can be used to generate more power. They have a lower operating temperature than solid oxide fuel cells, which means they don’t need such exotic materials. This makes the design a little less expensive. Phosphoric-acid fuel cell (PAFC): The phosphoric-acid fuel cell has potential for use in small stationary power-generation systems. It operates at a higher temperature than polymer exchange membrane fuel cells, so it has a longer warm-up time. This makes it unsuitable for use in cars. Direct-methanol fuel cell (DMFC): Methanol fuel cells are comparable to a PEMFC in regards to operating temperature, but are not as efficient. Also, the DMFC requires a relatively large amount of platinum to act as a catalyst, which makes these fuel cells expensive.