Table of Contents

ToggleFaults in induction motor

Small motors i.e. few HP and up to 415 V are protected by starters with inbuilt thermal overload relays and no volt release coil.

Large three phase motors i.e. greater than 100 HP and 3.3 kV, used for power station auxiliaries, fertilizer industries, chemical industries and petrochemical industries are protected by relays and circuit breakers.

A comprehensive motor protection arrangements are provided to achieve desired degree of security and dependability. Usual faults and abnormal conditions in case of induction motors are o

Overloading

Single phasing

Unbalanced currents

Reversed phase sequence

Under voltage

Stalling

Due to short circuits in the stator windings, high unsymmetrical current currents flows that cause negative sequence current in the rotor i.e. heating of rotor. Squirrel cage rotor generally does not develop faults, however, wound rotor motor suffers from rotor faults that increases stator current.

Thermal overload protection of induction motor

How to Overload Induction motor

Load connected with induction motor is a mechanical load. Increase in mechanical load decreases the speed of the motor i.e. increased slip. As slip increases, the rotor current of induction motor increases and that consequently increases the stator current too.

Increase in load more than rated load increases the slip above the rated slip and therefore stator and rotor current beyond the rated current. This state that

For increased stator and rotor currents, heat generated is more compared to heat generated at rated stator and rotor current. This heat does not affect stator or rotor conductors but increase in temperature damages the conductor insulation and gradually leads to thermal breakdown.

Thermal temperature rise

When motor is overloaded, the insulation does not reach a critical state immediately. Time within which the temperature reaches to a value equal to the maximum allowable limit of an insulation material is inversely proportional to the square of the current.

Hence different allowable time periods are derived for different overloads. The curve plotted between maximum allowable time vs multiples of the rated stator current is known as the thermal withstand characteristic of an induction motor.

Time within which the temperature rises to a maximum allowable value depends upon the datum temperature i.e. value of the temperature at the instant of overload.

When motor is overloaded in a cold condition i.e. from standstill, the time required for temperature to reach at maximum allowable limit is more than when motor is overloaded in hot condition i.e. from rated condition.

What to do if Thermal temperature rise

It is necessary that the motor needs to be disconnected from the supply before it reaches the respective time limit for a given overload, on the other hand disconnecting the motor much in advance from the given limit is undesirable because, in this case, the thermal overload capability of the motor is not fully exploited yet.

Hence, relay with the characteristics matched closely to the thermal withstand characteristics of the motor, is the best choice.

None of the overcurrent relay provides the characteristics that can be coordinated with the thermal withstand characteristics of a motor. A thermal relay with different time constants for two characteristic curves i.e. hot and cold are used.

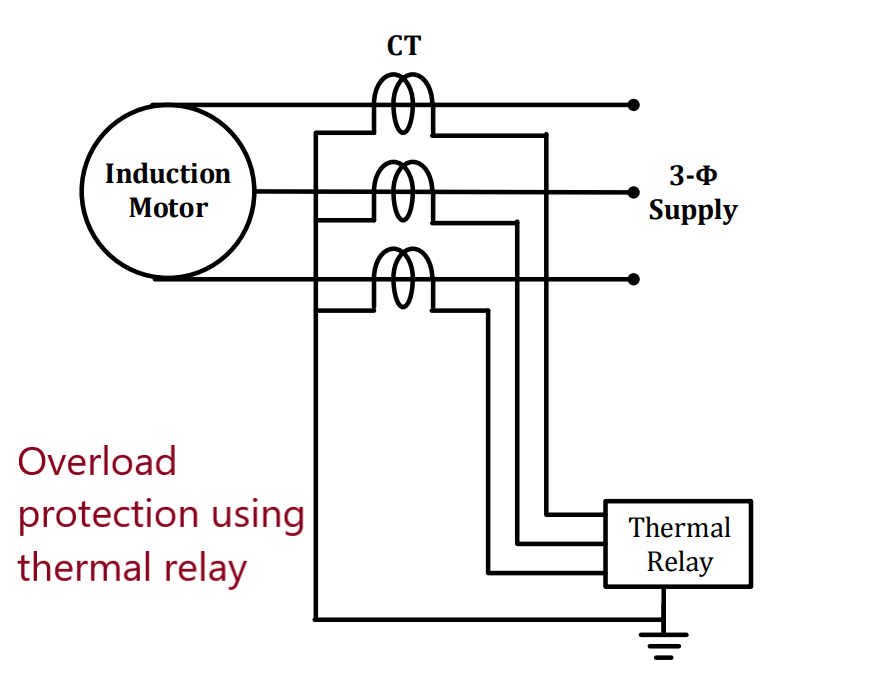

Overload protection using Thermal relay

While selecting a thermal relay for protection of an induction motor, it is required that relay should not operate for the motor starting current. This happens when motors with high inertia i.e. long starting times has started in hot condition.

In earlier days, bi-metal strip, thermocouple or resistance temperature detectors (RTD) were used. All these devices take a very long time to reset, thus hot restart of an induction motor was not possible.

Thermal relay uses electro thermal effect of the actuating current for its operation. The thermal element is a bimetallic strip wound into a spiral to obtain a greater length.

Bimetallic strip is made up of two metal strips with different coefficients of thermal expansion and joined together. When the bimetallic strip heats up, it bends and deflects, thereby closes the relay contacts.

For the overload protection of induction motors, thermal elements are directly heated by line current passing through it. Bimetallic strip of the thermal over load relay is energized through CT secondary.

When current through CT secondary reaches to the predetermined values for a predetermined time, the bimetallic strip is over heated and it deforms that causes relay contacts to close.

Relay contacts are arranged in such a way that if any one of the spirals moves differently from the other, due to an unbalance exceeding 12%, contact meets and causes normally closed (NC) contacts to open that further de-energizes the starter coil and stops the motor.

Pingback: Short circuit and single phasing protection of induction motor

Pingback: Negative phase sequence and stalling and Under voltageprotection of induction motor

Pingback: Start and Stall protection of Induction Motor