Transformers are vital components in electrical systems, responsible for stepping up or down voltages to facilitate efficient power transmission. To protect these valuable assets from internal faults, Buchholz relays are commonly employed.Let’s we understand function of Buchholz relay in Transformer.

Table of Contents

ToggleDefinition

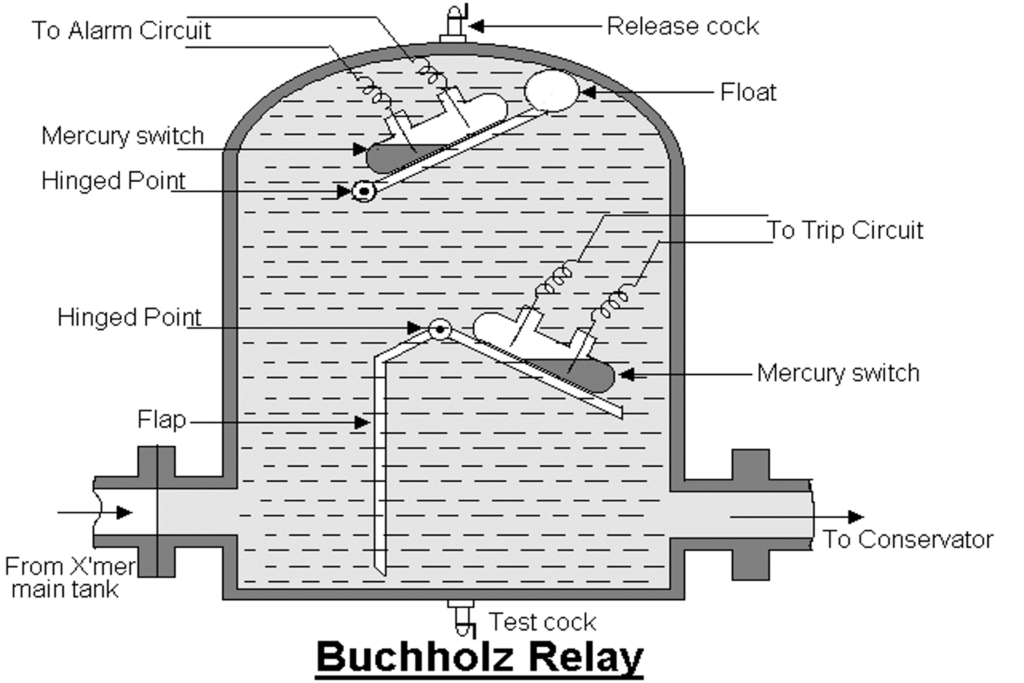

This relay is designed to detect transformer internal fault in the initial stage to avoid major breakdown. The upper float rotates & switches contacts close & thus giving alarm.

This is a gas and oil actuated relay for liquid immersed power transformers and reactors with conservator. The device is intended to detectGas release from the unit to be protected, Oil surge from the tank to the conservator, Complete loss of oil in the conservator.

Working of Buchholz relay

The buchholz (gas/liquid operated) relay is connected in the pipe work between the transformer tank and the conservator. If a valve is fitted to isolate the conservator, the buchholz relay is usually on the transformer tank side of the valve.

Under normal conditions, the relay is full of oil. Most faults occurring within oil filled transformers are accompanied by the generation of gas by the oil, due to liberation of heat. Such generated gas accumulates in the relay, thereby operating the float/flap switches.

With an incipient fault, gas is produced at a very slow rate and the upper float (alarm) switch will operate after a specified volume of gas has accumulated. The upper float (alarm) switch will also indicate the low level of the conservator.

When a major fault occurs, the gas is produced rapidly, resulting in a sudden surge of oil up to the conservator, thereby operating the lower float (trip) switch. The lower float (trip) switch will also indicate the drained oil level of the conservator.

To ensure successful operation of the relay, the pipe work on either side of the relay, and the relay itself, are all set at the same angle (2°-5 ° to the horizontal for single float relay and 3°- 7° to the horizontal for double float relay). A machined surface is provided on the housing of the relay to check the oil level. The arrow shown on the relay should point towards the conservator.

The alarm and trip terminals are clearly marked for function and polarity (locked during shipment), which should be set at service position before energizing the transformer. Check that the operating floats/flaps are freely functioning. When making the connection from these terminals in conduits, ensure that no condensation can drain into the terminal box.

In service, the top petcock should be kept closed. Before energizing the transformer, all air which may have collected in the relay should be released through the petcock.

Checking the floats operation manually

Close the both valves. (From Transformer and main conservator tank side)

Drain oil from the buchholz relay.

Top float makes contact as the oil gets lowered and gives Alarm.

If oil is further drained, bottom float makes contact and gives trip signal. After testing, both valves must be opened without fail and released the air from relay. Alarm & Trip circuit can also checked by shorting contacts externally by link.

Pingback: Types of Routine Test carried out on Power Transformer

Pingback: Key action taken while transformer trip or alarm in Buchholz and PRV and OTI/WTI

Pingback: Interview question of Electrical Power Transformer

Pingback: What is DGA(DISSOLVED GAS ANALYSIS) for transformer oil

Pingback: Types of Generator Protection in Power Plant

Pingback: Transformer Oil Properties and Characteristic

It’ѕ really a great and helpful piece of information. I ɑm glad that

you shared this useful info with us. Ⲣlease stay us up to date like this.

Thank you for shаring.

hi,

thanks for appreciation. Now, my focus on spread my website content to more readers.

To boost my moral, Please share my website to your friends and subscribe my Insta/Telegram/Whatsapp group.

Pingback: Cooling System Inspections in Power Transformer