Table of Contents

ToggleHow to Get an Ideal PCB through Double-Sided PCB Assembly

Electronics manufacturers must cope with the aggressive demand for reliable and quality electronics. A Printed Circuit Board or PCB is a key component in a fully functional electronic system. It is made of a dielectric substrate with conductive paths and pads to physically and electrically connect parts. Manufacturing companies are operating daily to produce and assemble printed circuit boards and deliver them to customers according to the planned demand.

PCB assembly services have a great concentration in the Asia Pacific region, with China suppliers taking big strides in the competitive market due to low cost, fast deliveries and latest technologies. Many companies have their respective strengths and weaknesses that can make or break a PCB project. In this article, we will talk about finding a reliable double sided PCB assembly partner.

What is Double-Sided PCB Assembly?

Before we go to the discussion of how to find a reliable assembly partner, let us deepen our understanding on double sided PCB assembly. Double-sided PCB assembly refers to the type of assembly process where electronic components are populated on both sides of the PCB. This means that copper layers are found on top and bottom sides to make component mounting possible.

PCB assembly can be done using Surface Mount Technology (SMT) or Through Hole Technology (THT). SMT is a direct method of mounting the components using solder paste while THT is an insertion type of process using the drilled holes on the PCB. In double-sided PCB assembly, the design can be solely SMT or THT or a combination of both techniques. Having both types of assembly techniques means that the supplier must have capabilities such as wave soldering, component insertion machines and an SMT line to fulfil the requirements. Below are the processes in a PCB assembly line:

- Solder Paste Printing.The pre-programmed solder paste pattern is printed into the bare PCB laminate using a stencil with apertures.

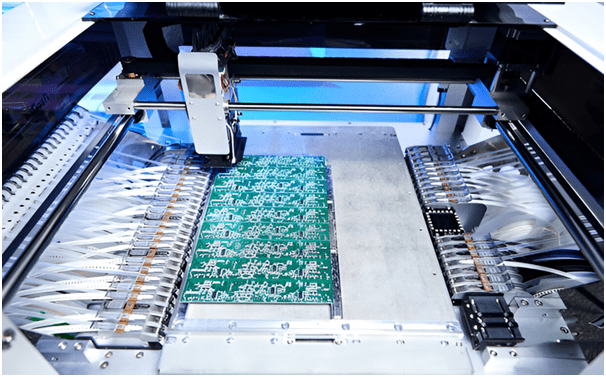

- Chip Placement.The robot arm of the Pick and Place machine picks the components and puts them in their designated locations on the PCB.

- The wet solder paste is cured using a reflow oven. The curing process joins the PCB pads, and the component leads to a complete metallurgical bond.

- Automated visual and x-ray inspections are carried out to identify faults on the printed circuit boards. Both soldering and placement issues can be detected to prevent them from getting shipped. Gross failures will require a more elaborate investigation.

- Changeover to the Next Side.After the first side has gone through the SMT processes, the next side will again proceed to the same processes but may have different machine parameter settings. The program of the machines are set to align with the next side PCB assembly.

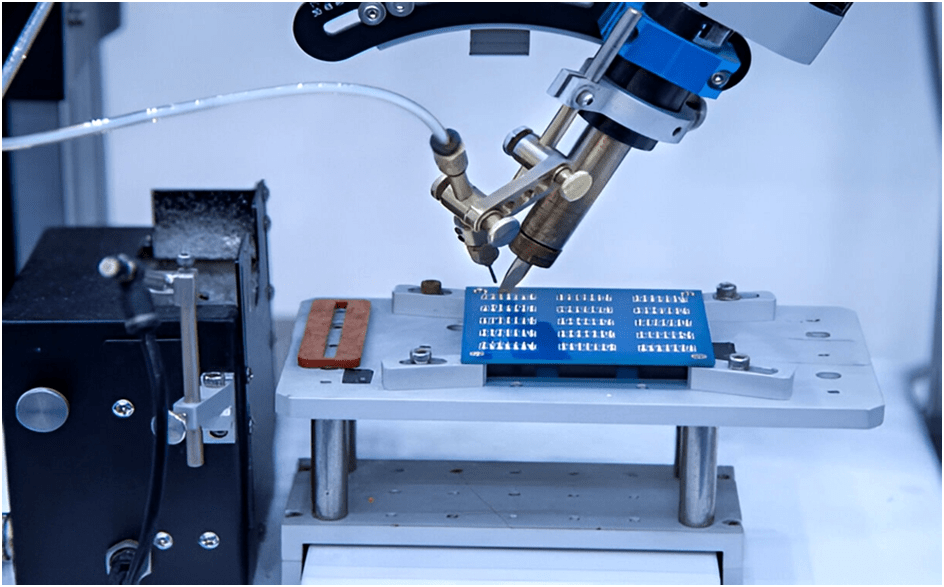

- Component Insertion and Wave Soldering (if Mixed Technology). Insertion process for through hole components can be done manually or automatically. Selective wave soldering is done to concentrate the soldering to the target component only.

Factors to Consider in Finding a Reliable Double Sided PCB Assembly Partner

Your investments can be maximised if systematic planning and careful supplier selection are done from the start. In the next section, as a reliable China PCB assembly supplier we will guide you through the factors to consider.

- Know your Business Needs. Establishing your business needs first will help identify the non-negotiable factors that qualify a supplier. The initial step is to know your primary objectives in finding a double sided PCB assembly partner. Whether you are looking for a low-cost or a turnkey type of business or a local supplier, all these aspects that are critical to the success of the project must be listed down. These business requirements will help gauge and decide on the right and the best PCB assembly supplier.

- Find a Low-Cost Supplier Wisely.Be practical during supplier selection.If your requirements are met by two suppliers, but one stands out due lower price, then it is an obvious choice to pick the supplier with a lower price. This must come with a sound decision wherein you must be aware of why and how the supplier is able to offer a lower price, may it be due to cheaper material cost or lesser assembly price.Dissecting the quote to its components will help you assess and compare potential suppliers.

- Choose a Technically Capable Supplier.Back-and-forth communication with the suppliers will be frequent, especially during the qualification stages. It is important to talk with a partner who is, as much as possible, on the same page as you. Technical capability means both expertise and a technologically equipped assembly line. A complete assembly line should have advanced machines with excellent productivity and accuracy to assemble and inspect good PCBs. A technically capable supplier is also able to anticipate potential failures by establishing out-of-control reaction plans and systematic analysis for every deviation.

- Be Critical of the Quality of the PCB.The right supplier must be able to assemble the PCBs within the defined specifications.To know if the PCB is within the criteria, the chosen assembly partner must have the tools and controls to verify the quality of the units. Quality should be set in every step with clear procedures and optimum settings. Quality should also be consistently achieved through regular audits and process assessments.

- Find a Supplier that Can Deliver PCBs Fast. The PCBs need not only be of low cost and good quality but they must also be delivered on time. Delivery is affected by several factors such as material lead time, processing durations and product dispositions. The assembly supplier should also have sufficient capacity, especially for fluctuating demands. Changeover processes must be carefully carried out to have minimal downtime and high machine utilization.

- Screen and Rank your Suppliers according to your Criteria. The initial screening of the suppliers will be based on your Must-Haves. Must-Haves are your fixed requirements that the supplier must be able to meet. After being able to shortlist your suppliers, you must have a list of criteria with individual weightage for you to quantitatively and objectively compare your potential suppliers. This can be a form of a matrix to easily sum up the scoring and see immediately which supplier bested the rest in terms of the combined criteria.

With havin so much written content do you ever run into any problems of plagorism or copyright infringement? My website has a lot of exclusive content I’ve either authored myself or outsourced but it looks like a lot of it is popping it up all over the web without my authorization. Do you know any techniques to help protect against content from being ripped off? I’d genuinely appreciate it.

Some truly wonderful posts on this internet site, regards for contribution.

I’d have to examine with you here. Which is not one thing I usually do! I take pleasure in reading a post that may make folks think. Additionally, thanks for permitting me to comment!

As soon as I detected this web site I went on reddit to share some of the love with them.

Wow! This blog looks just like my old one! It’s on a totally different subject but it has pretty much the same page layout and design. Excellent choice of colors!

Hi there! Would you mind if I share your blog with my myspace group? There’s a lot of folks that I think would really appreciate your content. Please let me know. Many thanks

You made some first rate factors there. I appeared on the internet for the problem and located most individuals will go along with along with your website.

Free video chat learn more and a convenient alternative to Omegle. Instant connections, live communication without registration, usernames, or phone numbers. Just click “Start” and meet new people from all over the world, whenever you like and whatever your mood.

Hello, for all time i used to check website posts here early in the morning, because i love to gain knowledge of more and more.

Escort directory listing Rio

https://bravomos.ru/ bravomos

Интерактивный флипчарт Samsung Flip Интерактивная панель LG Алматы: Премиальные решения LG CreateBoard для офисов Алматы.

Pretty section of content. I just stumbled upon your website and in accession capital to assert that I get actually enjoyed account your blog posts. Anyway I will be subscribing to your augment and even I achievement you access consistently fast.

aonang villa resort краби Узнайте, какое время в Краби, чтобы спланировать свои дела и насладиться отдыхом.

отдых на краби Посетите остров Ланте и насладитесь его красотой и живописными пейзажами.

краби сентябрь Ноппарат Тара Краби: красивьій пляж для прогулок.

Way cool, some valid points! I appreciate you making this article available, the rest of the site is also high quality. Have a fun.

Dead pent subject material, Really enjoyed studying.

купить выпрямитель дайсон пенза в наличии vypryamitel-dn-kupit-4.ru .

На 7k официальный сайт есть live-казино с русскими дилерами. Наоборот, рулетку и блэкджек очень люблю.

Посмотрел 7к казино игровые автоматы в демо, выбрал любимый слот. Потом уже на реальные деньги начал давить.

Регистрировался в казино через VK, удобно вообще не думал. Регистрация в 7к казино онлайн подтянула все данные автоматически.

Рулетка крутится плавно, никаких зависаний. 7k казино онлайн live-дилер общается по-русски, очень приятно.

Абсолютно стабилен в работе всегда здесь. Никогда не видел никаких сбоев или перебоев.

Новый адрес стабильно работает уже неделю. 7k рабочее зеркало без лагов и сбоев.

Платформа безопасна для игры на деньги. 7k официальный шифрование нормальное, данные не сливают.

Поддержка 7k отвечает быстро и по делу, это плюс.

7к казино официальный — регистрация простая, все по шагам и без путаницы.

С 7k удобно играть в любое время, сайт доступен 24/7.

Выводы на 7k приходят без задержек, проверял несколько раз.

Слоты на 7k идут стабильно, без подвисаний и вылетов.

Выводил 7k казино деньги уже несколько раз. Все приходит вовремя, без скрытых комиссий и задержек.

Все продолжает работать без остановок. Доступно круглосуточно, без выходных.

На севан кей казино кэшбэк еженедельный для активных игроков. Начисляется автоматически при выполнении нормы.

На 7k официальный сайт есть live-казино с русскими дилерами. Рулетку и блэкджек там прям люблю.

Поставил 7к казино рабочее зеркало на телефон для удобства. Теперь играю где угодно без ПК.

Казино севен кей приятно удивило скоростью загрузки.

7кей казик звучит по-простому, но работает стабильно.

вскрытие замков подходит, когда ключ потерян и важно быстрое решение, но дороже планового ремонта.

Сайт работает шустро, оптимизация заметна, но при слабом интернете мобильная версия предпочтительнее.

Зеркало нашел быстро и начал играть без проблем, но для вывода средств удобнее основной адрес.

На сайте бывают выигрышные серии, однако не стоит ожидать «легких» заносов без дисциплины.

Первый депозит 1000 рублей принес бонус 150% и 150 FS, однако на коротких сессиях отыгрыш сложнее.

На 7k официальный сайт понравилось live-казино с русскими дилерами, но для любителей редких столов выбор ограничен.

Бонус за депозит щедрый, вейджер x30 адекватен, но новичкам лучше начать с небольших сумм.

Проверял несколько раз — работает стабильно, добавил в закладки.

Приложение весит 50 МБ, ставится быстро, но браузерная версия быстрее обновляется.

По совету друга попробовал 7к казино официальный: регистрация простая, выплаты стабильные, но для любителей VIP-привилегий есть площадки с более агрессивной программой.

Платформа безопасна, шифрование нормальное, но перед крупной игрой лучше пройти полную верификацию.

Регистрация простая, анкеты минимум, но для вывода придется пройти проверку личности.

Выводил 7k казино несколько раз: комиссии не было, но скорость зависит от платежной системы.

Играл в 7k casino больше месяца: выплаты быстрые, но крупные суммы проверяются дольше.

Промокоды часто дают фриспины, но по выплатам выгоднее кешбэк, если играешь регулярно.

Лицензию проверил — все в порядке, но правила акций всегда читаю отдельно.

Рабочий адрес нашел в канале, резервные домены помогают держать доступ.

Сравнивал несколько площадок, и 7k casino показалось самым сбалансированным: выплаты быстрые, бонусные правила ясные, но для фриспин-хантеров есть более подходящие варианты.

Зеркало нашел быстро и начал играть, но для вывода средств удобнее основной адрес.

Слоты без лагов, но тяжелые игры требуют хорошего интернета.