Full name of SCADA is Supervisory Control and Data Acquisition (SCADA).

Table of Contents

ToggleWhy Power system automation required?

To maintain a state of balance between the production and the consumption of electrical energy in the power network with high quality and security at the lowest possible cost.

To find the best possible operating economy within the limits set by quality/security requirements as quality, security, and economy cannot be treated independently of each other.

Power system automation have

– Faster response and quicker decisions

– Faster restoration after breakdown

– Reduced start up, shut down, and re-configuration time

– Increased safety of personnel and of equipment

– Increased security, availability, reliability, and efficiency

– Less or nil dependence on high performance skills

– Optimization of resources, Reduction of losses, and

– lower operational cost

Power system automation require for manage Hazardous operations, repetitive operations, sequential operations with interlocks, complex operations.

To supply the power meeting the power quality standards like reliability – maintain uninterrupted supply, Availability – meet the demand, Purity – limit, within the permitted range, Frequency deviations,Voltage fluctuations, Transients, Harmonic distortions, Electrical noise.

What is Electrical substation automation using SCADA?

Electrical substation automation is the act of automatically controlling the substation via instrumentation and control devices. Substation automation refers to using data fromIntelligent electronic device (IED), control and automation capabilities within the substation, and control commands from remote users to control power system devices.

Substation automation is composed of several tasks.

Data acquisition-Data acquisition refers to acquiring, or collecting, data.

Supervision-Computer processes and personnel supervise, or monitor, the conditions and status of the power system using this acquired data

Control-Control refers to sending command messages to a device to operate the I&C and power system devices.

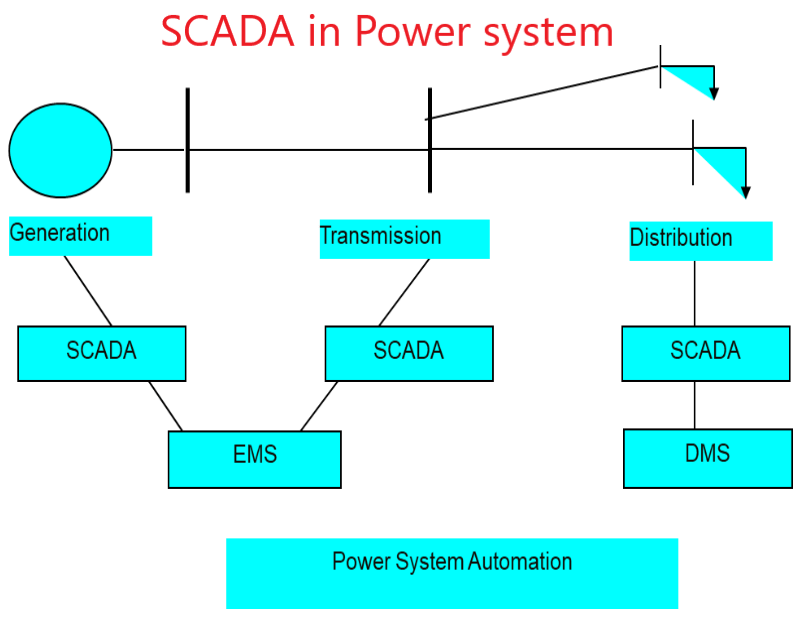

Supervisory Control and Data Acquisition System (SCADA)

Supervisory Control and Data Acquisition systems are indispensable tool in the operation of today’s power systems.

Through advancements in technology, most SCADA systems today operate in a scanning mode, providing multi-station operation, continuous self-checking of both the communication path and remote station equipment, and high-speed data acquisition.

SCADA requires two-way communication between the master station, normally at a higher-level control center on the power system, and stations with a remote (SCADA equipment), which are often at the substation or power plant level.

An operator at a master station can cause operations such as the opening and closing of breakers, the starting and stopping of condensers, and the changing of the taps on load-ratio-control transformers.

The operators can receive an indication that the operation has been completed. All of this can be done over a voice-grade (telephone) communication channel that distinguishes supervisory control from direct wire remote control; the latter requires one direct wire circuit for each controlled device.

In case of SCADA a single communication line is used for connecting to multiple substations and power plants.

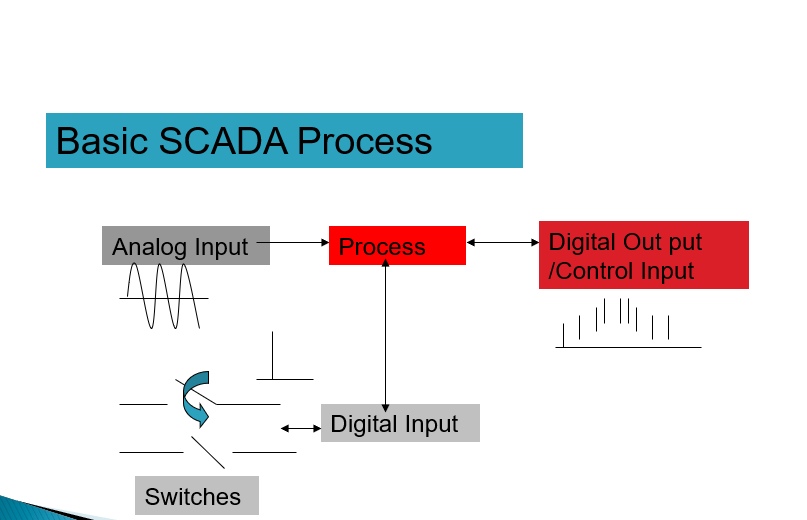

SCADA Process classified into three parts

- Input

Analog Input : Continuous Electrical Signals i.e. Active Power (MW), Reactive Power(MVAR), Voltage (KV), Frequency (Hz).etc..

Digital Input : Switching Signals High(1) or Low(0) Signal i.e. Breaker Close(high) or Open(low), Isolator Closed(high) or Open(low).

2. Process

The signals are converted into digital format.

Implement protocol between Master and Slave.

It operates with Real Time Operating System (RTO).

3. Output

The results are exposed with user friendly environment.

Through displays can be possible to control the substation and generating station.

Data Acquisition in Power system

Data Acquisition in Power system like power plants,in substation and from field. We understand below in detail.

In Power Plants

Power plants use different type of fuels including coal, water, nuclear, gas, diesel and wind.All the plants have control room to for controlling power production.

There is also a substation at stepping up or power take out point by the transmission company. The control room can be equipped with control system such as DCS or PLC or SCADA to automate the operations.

In Substations

The power transmitted from generating substations is received at transmission substations operating at 110,132, 220 or 400 KV.

The voltage is stepped down to distribution voltage levels such as 110, 66 or 33KV and the lines at these voltage levels are taken to various cities and town for distribution.

These lines are received at distribution substations and again stepped down to 33 or 11KV and taken to the places of consumption and stepped down to 440 volts by pole mounted transformers for giving it to consumers.

Substations without stepping up or down activities are called switching stations.

There are number of HVDC substations in India. When the distance is very long, it is better to transmit the power using HVDC lines. These lines are also used for connecting two power systems operating at different frequencies. For example, there is a 50Hz and 60 Hz power systems in Japan and they are linked through HVDC.

There are number of recording, indicating, controlling, measuring, and protection devices at substations that can be interfaced to SCADA systems for power system automation.

In Field Data

SCADA system could gather data pertaining to every event or activity on the power system. The operations of entire power system is often centralized into one massive operating center.

In India, this could be State Load Despatch Centre (SLDC) for state owned power systems, and Regional Load Despatch Centre (RLDC) for central government owned power systems.

This centre would start up, monitor, and shut down power plants, operate the transmission system, perform sectionalization and switching operations, and generally operate the whole system.

(1) The data could be classified into two main categories:

Operational (real-time) data and used by:

- Power system operator

- EMS & DMS programs

Non-operational or equipment condition monitoring (ECM) data and used by:

- Maintenance division

- Relay division

- Revenue department

Advantages of SCADA

Viewing of real time data

Supervisory control

alarms for any abnormal condition in the system

system studies can be performed

planning of electrical power position in the state

user friendly report generation

web integration

energy management

Disadvantages of SCADA

Skilled personnel are required to operate the system

Initial cost high

Partial implemented open system architecture

Protocols for certain data collection are yet to be standardized