Table of Contents

ToggleTypes of Distribution Transformer

Amorphous Core Transformer

CRGO Transformer

CSP Transformer

Dry Type Resin Cast Transformer

Load Shedding (LSTC) transformer

Amorphous core

Non-crystalline structure lends to material unique properties metallic glass alloy combine the strength and hardness characteristics of silicon with plasticity and toughness of metal

Use of such Perm alloy metal for transformer core will reduce the core loss more compared to CRGO core

It is the combination of iron, nickel and cobalt with B,C,Si,P

Initially it was Au75 Si15. Thereafter many combinations of metal found and converted molten metal. Nowadays Fe78 B13 Si9 is Metaglas combination best suited for production of transformer core.

properties of Amorphous metal

Higher Electrical Resistivity

High Tensile strength

More flexibility without losing hardness

Ease of Magnetization

Ability to change magnetic orientation

Thickness of the core is 0.023-0.025 mm

It is available in the form of ribbon and hence wound core is made cover larger surface area

Almost 75% of iron loss is being reduced due to magnetic properties of amorphous core.

It cannot dumped or reuse once it declared as a scrap

For power transformer manufacturing is not easy, skilled employees are required to handle thin core compared to CRGO.

Thickness :0.023 mm

Annealing Temperature :360°C

Saturation Flux Density :1.58 Tesla

Core losses are from 0.15 to 0.25 watt/kg

Better Demand side management can be done using A’phous

Less noise level and less magnetostriction

Less temperature rise of core

CRGO Core Transformer

CRGO is called as a Cold Rolled Grain Oriented Silicon Steel.

Conventionally, CRGO core uses M-2 to M-6 grades over the years.

Energy saving is most importance factor nowadays in electrical sector and hence to minimize core loss ZDKH, Hi-B silicon core is used.

Silicon helps to increase the resistivity of steel about 25 μΩcm for low carbon steel which eventually reduce eddy current loss.

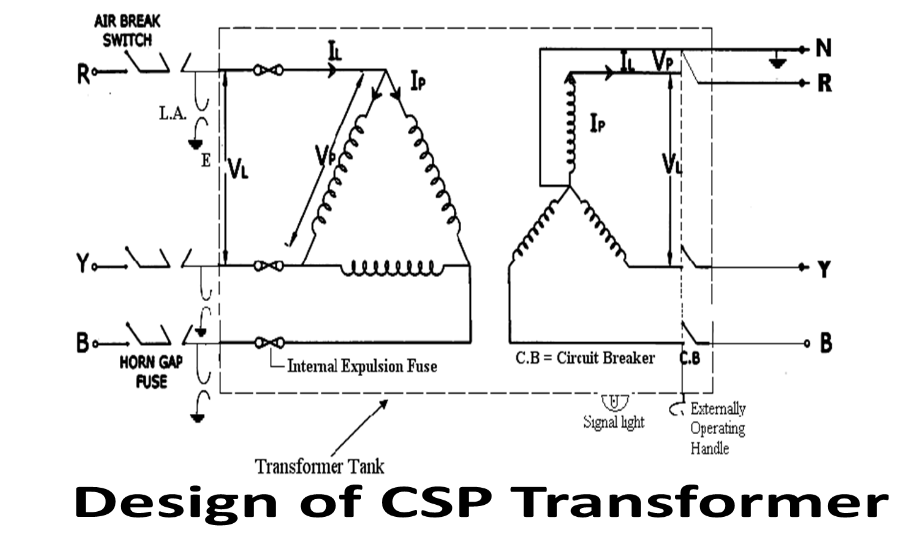

Completely Self Protected(CSP) Transformer

CSP Technology shows the way out for the distressing situations arising by usage of conventional type DTRs.

CSP Technology enables the transformer to protect itself from faults.

- Outdoor type 3 phase CSP Type DTR up to and including 100 KVA

- 11 KV/433-250 V for 16,25,63 & 100 KVA

CSP system has three essential components

- Primary Fuse: Expulsion fuse for internal protection of transformer

2.Secondary Circuit breaker: For overload and short circuit protection

- Surge Arrestor: For lightning protection

Coordination of protection system in CSP Technology is achieved in such a way that the circuit breaker clears both overload and short circuit faults on load side, whereas the internal fuse at HV side mostly takes care of Transformer winding and other internal faults.

Primary(HV) Fuse

Ideally the primary side fuse for an outdoor transformer should be internally mounted (tamper proof) and the rating is determined that it should not blow for secondary faults and exciting current surges. British electricity authority have found by experience that when fuse is rated to stand 12 times the full load current for 10 ms it meets the requirement.

Secondary (LV) Circuit Breaker

This provides the overcurrent protection to the DTR. In order to perform this critical function its thermal characteristics and the time response to the thermal changes must match those of the Transformer.

Thermal protection of the transformer

The average temperature of the transformer winding at any time, is given by the average oil temperature+ the average winding temperature rise due to instantaneous load current.

The CSP transformer gives adequate protection against overloads, short circuit and surges which are the main causes of failure of majority of the transformers. All the components required for CSP system are manufactured in India and the extra cost of CSP transformer is approximately 10% over that of conventional transformer for a typical rating of 100 KVA. Considering the advantages over conventional transformers the extra COST is definitely justified.

Dry Type Resin Cast Transformer

Fire resistant

Better Short Circuit Withstand Capability.

2 to3 Times expensive

Ratings- 3Phase.11/.433-.250KV, 25,63,100 kva, Out-Door Type.

Both HV/LV Windings Impregnated And Cast Under vacuum Into Moulds of Fibre Glass Reinforced Epoxy Forming Rigid Tubular Coils

All Iron Parts Except Core Be Hot Dipped Galvanized.

Advantages of cast resin transformers

Non-hygroscoping insulation:

The Cast Resin Transformer is non-hygroscopic and hence will not absorb moisture during service or when stored, whereas the oil cellulose insulation system used in Oil-filled Transformers have high affinity to moisture and as a result any ingress of moisture will deteriorate the electrical strength of Oil-filled Transformers. The non-hygroscopic nature is highly beneficial because the Transformer can be immediately switched-on, even after a prolonged shut down.

Fire safety:

The Cast Resin Transformer is non – inflammable and will not spread fire to its surroundings or will not explode.

High mechanical strength:

As the coils are cast in epoxy resin ,the mechanical strength is extremely high and there is no chance of the Transformer failing under short circuit. This aspect is of utmost importance in India where experience shows that short circuit accounts for a large number of Transformer failures.

No leakage or pilferage of liquids:

Leakage or pilferage of insulating liquid is a general problem associated with liquid-filled Transformers and there is no question of leakage or pilferage of liquid and consequent failures.

Maintenance free:

Once installed, the Cast Resin Transformers require practically no maintenance and this saves on operating cost of the equipment.

Protection against corrosive atmosphere:

The complete vacuum impregnation and filling of the primary and secondary coils- provide extremely good protection against atmospheric pollution. The glass reinforced resin castings are impervious to most common gasses, chemical fumes etc., and these transformers are best suitable for industrial applications.

Partial discharge free:

Due to the special advantages of the glass fibre reinforced unfilled system, the Cast Resin Transformers are partial discharge free.

Application of Dry Type Resin Cast Transformer

Varied applications

Distribution system

SERVICE SECTOR

Hospitals

Banks

Schools

Shopping and cultural centers

Management centers

INFRASTRUCTURES

Airports

Military installations

Ports and off-shore installations

Step up Transformers:

Wind parks

Photovoltaic systems

Cogeneration systems

Industrial applications

Cast Resin Transformers manufactured using glass reinforced unfilled system are superior and it offers several advantages economy in operation and long life expectancy. Due to the benefits discussed these are ideally suitable for application in generating stations, high rise buildings, hospitals, air-ports, factories residential areas etc.

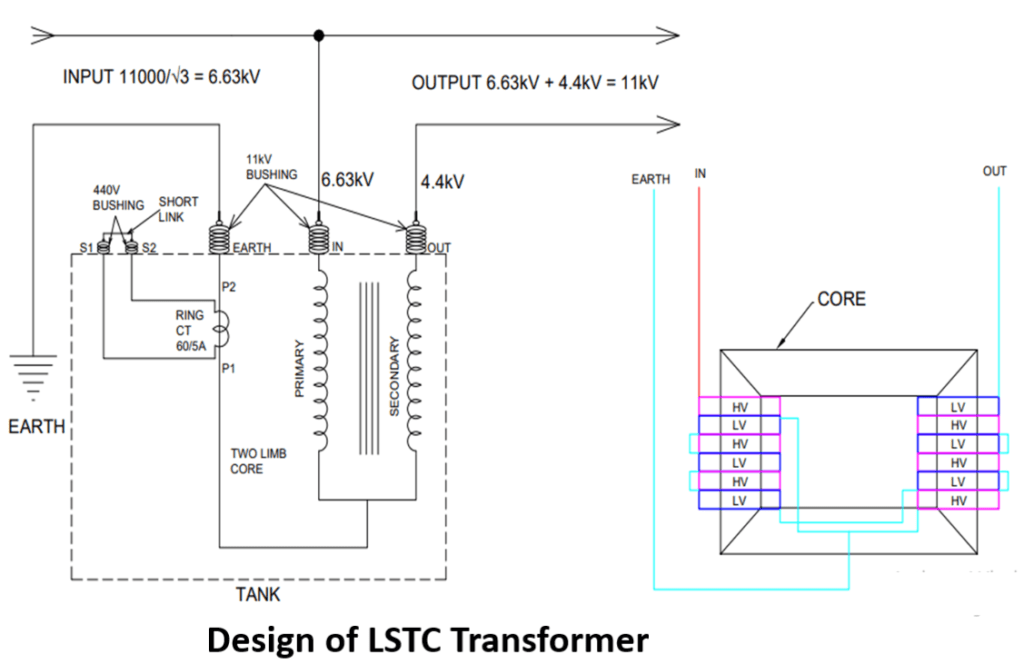

Load Shedding (LSTC) transformer

Load shedding transformer (LSTC/SDT) is utilized for getting single phase power supply in agriculture field for lighting purpose after completion Ag 8 hours three phase schedule.

Ratio of this transformer is set to 1.4 to 1.6 of HV to LV voltage.

R phase shall be solidly grounded.

Strong earthing having value less than one ohm shall be conducted.

CT coil should be directly connected in earthing strip.

Tripping relay is connected at SS end.

Hey very nice web site!! Man .. Excellent .. Amazing .. I’ll bookmark your web site and take the feeds also…I’m happy to find so many useful information here in the post, we need work out more techniques in this regard, thanks for sharing. . . . . .

Pingback: Continuous On-Line Monitoring of Transformer

Thanks for another informative web site. Where else could I get that type of information written in such a perfect way? I’ve a project that I’m just now working on, and I’ve been on the look out for such info.

I’d always want to be update on new blog posts on this internet site, bookmarked! .

I have been exploring for a little for any high-quality articles or blog posts in this kind of area . Exploring in Yahoo I eventually stumbled upon this website. Studying this info So i am glad to show that I’ve a very just right uncanny feeling I came upon just what I needed. I such a lot indubitably will make certain to don¦t overlook this site and give it a look on a constant basis.

Thanks for helping out, good info. “You must do the things you think you cannot do.” by Eleanor Roosevelt.

certainly like your website but you have to check the spelling on several of your posts. Several of them are rife with spelling problems and I in finding it very troublesome to tell the truth nevertheless I will definitely come back again.

Great wordpress blog here.. It’s hard to find quality writing like yours these days. I really appreciate people like you! take care

Hello. excellent job. I did not expect this. This is a impressive story. Thanks!