Table of Contents

ToggleVibration in Transmission Line conductor

The overhead transmission lines experience vibrations in the vertical plane and are of two types. However, these are not to be confused with the much slower swing of the conductors in the horizontal plane due to simple wind deflection:

- Aeoline vibrations,

- Galloping or dancing of conductors (vibration).

The first one is of high frequency and low amplitude. The frequency is of the order of 5 to 40 c/s and the amplitude of the order of 2 cms to 5 cms with a loop length of 1 metre to 10 metres. It appears to be a condition of their formation that the wind velocity shall be quite low, 4 to 15 km/hr, that it shall be steady and free from gusts, uniform over a wide area and free from eddies.

The galloping or dancing of conductors are the low frequency high amplitude vibrations of the conductors. The frequency is of the order of ¼ to 1(1/2) cycle/sec and the amplitude is about 6 metres. Whereas the former are forced vibrations, the latter are of the self-excited type. These vibrations are caused due to the wind when it blows past a non-circular conductor. Once this starts it builds within itself and the vibrations may become very large and may result in flexure fatigue in the conductors or there may be flashover between conductors of different phases. This may lead to outages in the systems.

Aeoline Vibrations:

While these vibrations are not of themselves harmful, however, they may give rise to troubles at points where free vibration is restricted. At a heavy anchor clamp, e.g., a travelling wave will be reflected back with a momentary bending of the cable about the mouth of the clamp, and even the provision of a large radius at the mouth is not a complete safeguard, since the wave will result in impact between the conductor and radius which, continuously repeated, may damage the wires.

A light anchor clamp very freely supported will reduce this hazard considerably and, in cases where vibration is not severe, will in probability provide adequate protection at dead-end points. If the clamp has very low inertia so that it can vibrate with the conductor without substantial time lag, the bending of the conductor as well as the impact between the conductor and clamp will be greatly diminished, thus resulting in less danger of conductor failure.

How to reduce Vibration?

Besides the design of the clamp and accessories, the vibration problem has been solved by the use of special devices which fall into two groups (a) reinforcement or armour rods, and (b) Vibration dampers.

Armour rods

Within the first group will fall the Varney system of reinforcement, in which the conductor, where it lies in the suspension clamp, is surrounded by a spiral layer of small round rods, preferably tapered at each end, and appreciably larger in diameter than the individual wires of the conductor. These rods, in effect, give at the point of suspension a stranded cable of much larger diameter than the actual conductor, so that they provide a resistance to bending equal to that of a much larger conductor; whereas the energy which must be absorbed by this bending is only that produced by the wind acting on the small conductor itself. Armour rods also provide excellent protection against flashover and have been used for this purpose in various cases where no vibration was experienced or anticipated.

Vibration Damper

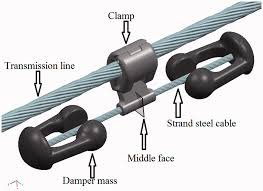

A true damper, however, is a device specially designed to absorb the vibrational energy, and thereby prevent the occurrence of any vibration at all. Many designs have been put forward, among which is the stock-bridge damper, an extremely simple, nevertheless effective device for suppressing high frequency vibrations. It consists of two hollow weights of special shape fixed at either end of a length of flexible steel cable which is itself fastened to the conductor a tits midpoint by means of an aluminium clamp.

The weights are of galvanized iron or in the smaller sizes of zinc and the flexible cable is protected by enclosing it in a water-tight flexible aluminium tube.

Among the special features of the design is the method by which the clamp is attached to the conductor. An efficient grip is obtained by the use of only one bolt, and the ease of application is such that these dampers may, if necessary, be attached to a line while it is alive, making use of special long handled tools.

Two dampers are required for each point of suspension of the conductor, one on either side, clamped to the conductor at appropriate distances, depending on the conductor size. Each span of conductor will thus contain two dampers and this is ample for normal conditions. For very long spans, however, it may be desirable to install additional dampers.

The damping action of the stock-bridge device is due to the dissipation of the vibrational energy of the conductor by hysteresis and inter-strand friction in the flexible damper cable. Vibration in the main cable causes relative motion between the central clamp and the weights of the damper, resulting in the bending of the flexible cable through a magnified arc and a consequent absorption of energy.

The damping effect is automatic, the first tremor of vibration in the conductor being damped out before the amplitude is able to build up to a measurable magnitude. Some degree of vibration in the conductor must occur before the damper is brought into operation, but the amount is extremely small, and a conductor fitted with a damper remains quiescent except for a barely perceptive quiver.

Dancing of Conductors

To damp these oscillations it is required to make the conductor circular. For stranded conductors PVC tape is wrapped to make the conductor circular. This method is useful only when sleet formation is not there on the conductor. For this situation, the sleet or ice coating could be reduced by increasing the I2R loss on the conductor which of course is not a practical solution to the problem.

Pingback: Procedure For Stringing of Conductor - Electricalsphere

Sau khi điền xong các thông tin cần thiết, bạn cần kiểm tra lại để đảm bảo không có sai sót. rtp slot365 Tiếp theo, bạn sẽ nhấn vào nút “Đăng ký” để hoàn tất quá trình. Một số trường hợp, hệ thống có thể yêu cầu xác minh qua mã OTP gửi về số điện thoại hoặc email để tăng cường bảo mật. TONY12-26