Table of Contents

ToggleWhat is Electrical heating?

Electric heating is a process in which electrical energy is converted in to “heat energy.” Electric heating works on the principle of “joule heating.” (An electric current through a resistor converts electrical energy in to heat energy).

Electric heating is based on the principle of that when electric current passes through a medium heat is produced. Let us take the case of solid material which as resistance R ohms and current flowing through it is I amps for t seconds than heat produced in the material will be H = I2Rtjoules.

Heat is the form of energy that is transferred between two substances at different temperatures. The direction of energy flow is from the substance of higher temperature to the substance of lower temperature. Heat is measured in units of energy, usually calories or joules. Temperature is the measure of hotness or coldness of matter. Stated another way, temperature is the average kinetic energy per molecule of a substance.

Domestic application of electric heating

Room heater for heating the building

Immersion heater for water heating

Hot plates for cooking

Electric kettles

Electric oven for baking products

Electric toasters etc

Industrial applications of electric heating

Melting of metals

Electric welding

Molding of glass for making glass appliances

Baking of insulators

Molding of plastic components

Heat treatment of pointed super passes

Making of plywood

Advantages of electric heating

Economical: Electric heating equipment is cheaper; they do not require much skilled persons; therefore, maintenance cost is less.

Cleanliness: Since dust and ash are completely eliminated in the electric heating, it keeps surroundings cleanly.

Pollution free: As there are no flue gases in the electric heating, atmosphere around is pollution free; no need of providing space for their exit.

Ease of control: In this heating, temperature can be controlled and regulated accurately either manually or automatically.

Uniform heating: With electric heating, the substance can be heated uniformly, throughout whether it may be conducting or non-conducting material.

High efficiency: In non-electric heating, only 40–60% of heat is utilized but in electric heating 75–100% of heat can be successfully utilized. So, overall efficiency of electric heating is very high.

Automatic protection: Protection against over current and overheating can be provided by using fast control devices.

Heating of non-conducting materials: The heat developed in the non-conducting materials such as wood and porcelain is possible only through the electric heating.

Better working conditions: No irritating noise is produced with electric heating and also radiating losses are low.

Less floor area: Due to the compactness of electric furnace, floor area required is less.

High temperature: High temperature can be obtained by the electric heating except the ability of the material to withstand the heat.

Safety: The electric heating is quite safe.

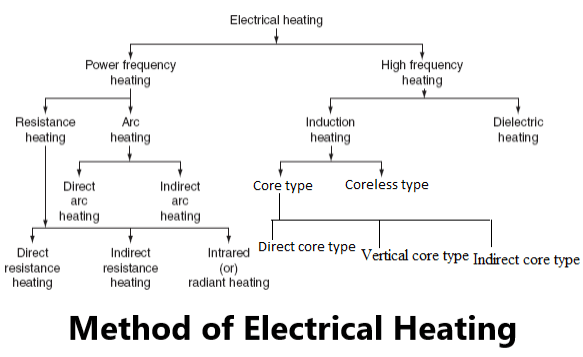

Method of Electrical Heating