Table of Contents

ToggleConstruction of Ceiling fan

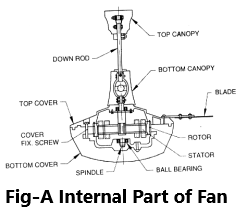

The parts of the ceiling fan are shown in Fig.A and B The key components are the following;

Electric motor

Single phase capacitor start and run induction motor, rated at 230 V ± 10 % at a frequency of 50 Hz, is normally used in ceiling fan. This motor has two parts namely stator and rotor. The stator, made op laminated silicon steel, employs two windings called as starting and running windings placed 90 degree electrical apart. The starting torque depends on sine of angle between starting winding and running winding current. So Capacitor is used produce required phase shift between these current and hence to produce high starting torque and will be connected in series with starting winding. Normally in ceiling fan, an electrolytic capacitor of 2.5 mF±5% will be used. The capacitor and starting winding will be in circuit during running also and hence improve the power factor. So this motor will also called as permanent capacitor induction motor. Rotor employs 1-phase squirrel cage winding.

Blades

The blades are made of sheet steel or aluminum sheets. Aluminum blades are lighter than steel sheet plates and also improve the efficiency of the fan. The ceiling fans normally have 3 or 4 angular blades. The four blade fan gives more air circulation as compared to three blade fans. The blades are 120o mechanically apart and may be curved at an angle of 10o.

Blade flanges

Alternatively called as blade irons, blade arms or blade holders. These are metal arms which connect the blades to the motor.

Canopy/Switch Cup

There are two canopies top and bottom, made of metal cylinder, placed along suspension rod. Top canopy is mounted such that it covers the hook, nut, and bolt. Bottom canopy is mounted below and in the centre of the fan’s motor. This is used to conceal and protect various components, which can include wires, capacitors and switches. On fans that require oiling, the bottom canopy often conceals the oil reservoir which lubricates the bearings.

Ball bearing

Friction free and noise free movements of rotating parts are ensured by providing ball bearing between rotating and stationary parts. The ceiling fan may have single or double ball bearings. The bearings made of high quality steel are regularly greased with superior quality for its long life and noise free operation.

Suspension rod/Down rod

It is made of rigid galvanized steel pipe of appropriate length and diameter. This metal pipe is used to suspend the fan from the ceiling. One end of the pipe is bolted or screwed at the place specially made on the motor body to receive the suspension rod. The other end of the suspension rod is attached to two plates, to from a “U” shaped joint, with the help of a nut and bolt (with additional lock nut). The “V” shaped end of the rod is further attached with the ceiling hook with the help of bolt and nut with additional lock nut and split pin to eliminate chances of disconnection at any stage.

Speed regulator

It is used to control the speed of the fan. The speed of the fan can be varied by changing the applied voltage. The most common method to vary the applied voltage is i) by tapped field resistors and ii) by tapped series inductors. Nowadays thyristor based electronic type regulators mostly used compared to above mentioned electric types. The electronic fan regulator is fault free, has long life and more efficient as compared to electrical fan regulators. The schematic diagram of a fan with resistance type regulator is shown in Fig.

Working of ceiling fan

The working of fan is that they do not actually reduce the temperature of the room but due the circulation and wind motion they result in surface cooling and give a breezy feeling. Electricity is used to empower the fan motors and due to the scientific design of fan blades we get the breeze, a man made phenomenon, similar to wind creation. The fan blades create a draught and the warmer air goes up. When that air is pushed down with a force, we get better air circulation. There is set parameters that need to be taken into consideration before you install the ceiling fan, care should be taken that it is not too close to the ceiling otherwise the draft will not be proper and should be at a safer distance from the reach of the people in the house.

Fault solution

Fault | Causes | Remedy |

Noise | It is due to worn out bearings and absence of lubricating oil or grease. Humming or induction moise is due to non-uniform air gap owing to the displacement of rotor. | The bearings must be replaced if worn out; otherwise lubricate with proper lubricant. Dismantle and reassemble properly. |

Low speed | It is due to defective or leaky capacitor. Low voltage applied. | Replace the capacitor with one of the same value and voltage. Check the voltage and adjust if possible. |

Jamming of rotor | It is due to misalignment | Dismantle and assemble properly after proper lubrication. |

Not starting | Low applied voltage Supply failure Open in winding. Condenser open or short. Open in regulator resistor/ switch. | Check the voltage and adjust if possible. Check the supply points at switch, regulator ceiling rose and the terminal of the fan. Check for the continuity of auxillary and main winding. Check the capacitor with a Megger. Check for open or loose contact in the resistor or contacts. |