Table fan is propeller bladed fan having two or more blades is directly driven by an electric motor. It may be a bracket mounted wall table fan, kitchen fan or a portable table fan. Four blades table fans are also available to obtain more air delivery.

Construction of Table Fan

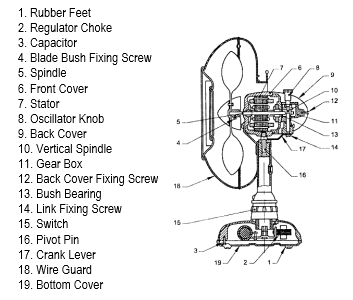

The parts of the ceiling fan are shown in Fig. The key components are the following;

Enclosure

The place where the fan motor is mounted may be totally enclosed type or ventilated type. The enclosure material is generally cast iron.

Body and stand

The body of the table fan is usually made of die cast iron or aluminum alloy. The body is fitted or mounted to the heavy base stand, made of die cast iron or aluminum.

Motor

The table fan motor is mostly of a single phase capacitor start and run or rarely shaded pole type motor. The operating voltage of the motor will be 230 V ± 10 % at a frequency of 50 Hz. This motor has two parts namely stator and rotor. The stator, made op laminated silicon steel, employs two windings called as starting and running windings placed 90 degree electrical apart. The windings are placed in slots of laminated iron core. The starting torque depends on sine of angle between starting winding and running winding current. So Capacitor is used produce required phase shift between these current and hence to produce high starting torque and will be connected in series with starting winding. Normally in table fan, an electrolytic capacitor of 1.5 mF. Rotor employs 1-phase squirrel cage winding.

Blades

The blades, 3 or 4 in number, are fabricated from Aluminum sheet foe light weight. Modern table fans have molded blades of plastic material. The blades are fully balanced to ensure proper and smooth air delivery. The sweep of the blade varies from 100 to 400 rpm. The speed of the fan is limited to less than 1000 rpm. The blade assembly is fitted to the rotor shaft with a grub screw.

Guard

The guard is provided for adequate protection against personal injury. The front and rear of the fan guards are made out of wire mesh which covers the blade. It prevents the external objects coming in contact with the blade thus preventing an accident. The front guard is normally detachable and rear one will be permanently fixed to the body of the fan. The diameter of the guard wire is normally not less than 1.6 mm and not more than 10 mm.

Bearing

Most of the fan motors use phosphor bronze sleeve bearings mounted in the bell housings and use felt wick to supply oil to a small hole drilled through the bearing wall. The felt wick receives oil from a hole in the bell housing. Most of the fan motors use an integral ball bearing to locate the rotor. It is held in place by spring clips in the bell housing and is self-aligned.

Mounting

It means attaching the fan system (motor and blades) to its base. The mounting may be rigid (change of direction is by turning the entire fan body) or semi-rigid (the direction of draught can be altered without changing the direction of the base).

Oscillating mechanism

The oscillating unit mechanism consists of a worm gear or a motor shaft that engages a gear on a short jack with the gear on the vertical shaft. A disc attached to the lower end of the vertical shaft rotates at a very slow speed and by means of a strong crank lever attached to the disk at one end and the motor at the other end, the fan is caused to oscillate. This principle is employed in most oscillating units built into the gear mechanism with a compression stud device. This design permits the fan to be used either as a stationary or an oscillating model.

Supply cord

A 3 core, flexible sheathed conductor of length about 2 m is used which has an earthing conductor along with other two conductors. A cord grip is also inserted at the entrance point of cord into the body.

Fan regulator

It is built within the table fan. There are so many types of regulators i) Resistance wire type ii) Choke or inductor type iii) Capacitor type and iv) electronic type. Generally coiled resistance type regulator is used in table fan.

Working of Table fan

The working of fan is that they do not actually reduce the temperature of the room but due the circulation and wind motion they result in surface cooling and give a breezy feeling. Electricity is used to empower the fan motors and due to the scientific design of fan blades we get the breeze, a man made phenomenon, similar to wind creation. The fan blades create a draught and the warmer air goes in. When that air is pushed away with a force, we get better air circulation.