Table of Contents

ToggleFunction of Hair Dryer

We are all very familiar with the daily routine; we wash our hair and then automatically pick up the hair dryer, flip the switch and there is the hot air to dry quickly and let us get on with the day. There are good reasons for people to dry their hair with a hairdryer, going out with wet hair especially in the winter can be bad for our health, and lead to catching colds and chills. A hair dryer also called blow dryer is an electrical device which can be used for styling and drying the hair by speeding up the evaporation of water from the hair’s surface.

Working of Hair Dryer

The working of Hair dryer is much simpler and most of its mechanisms revolve around its fan. When the dryer is switched on, the electricity moves to the windings of the motor of the fan. And here the electrical energy is transformed to kinetic energy as it provides momentum to the fan. The motor and the attached fan both spin. The centrifugal movement of the fan blades draws air in through the small round air inlets in the side casing of the hair dryer. These holes are covered by a safety screen that prevents other objects (such as strands of your hair) from being sucked in as well.

The airflow thus generated by the fan is forced through the heating element by the shape of the hair dryer casing. These coils are designed to get heated quickly using its electrical resistance and electric current. When the air initially enters the barrel, it is much cooler than the nichrome wire, so heat flows from the wire to the air, which becomes very hot. As the air is pushed along by the fan and convection, it is replaced by cooler air and the cycle is repeated.

The hot air streams out the end of the barrel. The hot air thus emitted from a hair dryer increases the temperature of the air surrounding each strand of hair. Since warm air can contain more moisture than air at room temperature, more water can move from your hair into the air.

Types of Hair Dryer

Portable type hair dryer

Saloon (Bonnet) type hair dryer

Both the hair dryers supply hot air to dry the wet hair on the common principle of blowers with a heating element.

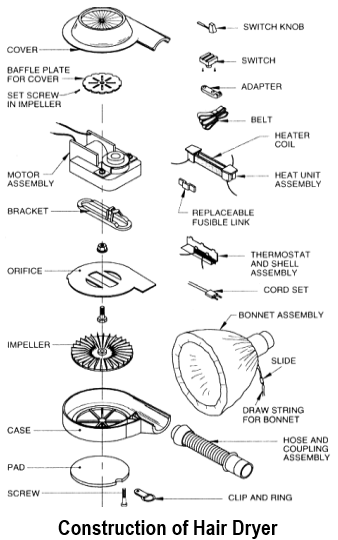

Construction of Hair Dryer

A hair dryer needs only two parts to generate the blast of hot air that dries the hair:

a simple motor-driven fan

a heating element

But in additon to above parts, most basic models will have have two switches, one to turn them on and off and one to control the rate of airflow. Some models have an extra switch, called thermostat switch, used to regulate the temperature of the airflow.

The fan should probably be called a blower; the blade is shaped like the impeller on a vacuum cleaner and mounted in a housing which is connected to the outlet duct. Most motors are of single speed, shaded pole motors particularly in the smaller models. Some of the larger and more elaborate types have multiple speed motors or solid state control units on Universal motor. Early hair dryers put out only about 100 watts of heat. But nowadays hair dryers producing up to about 2,000 watts are available, drying hair considerably faster. The motors will be designed to work on 230 V, 1-phase, 50 Hz AC supply.

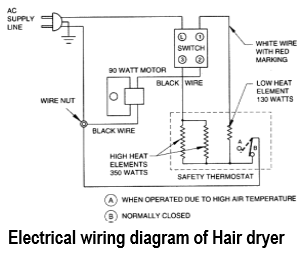

Heating element

The heating element in most hair dryers is a bare, coiled nichrome wire that’s wrapped around insulating mica boards. Nichrome wire is an alloy of two metals, nickel and chromium. This alloy is used in heating elements in a number of household products, from curling irons to toasters. Nichrome wire has two features that make it a good producer of heat:

It’s a poor conductor of electricity compared to something like copper wire. This gives the alloy enough resistance to get hot from all of the current flowing into it.

It doesn’t oxidize when heated. Other metals like iron rust pretty quickly at the temperatures used in toasters and hair dryers.

The heating element is of the open wire type, wound on thin mica insulating board. Something seen more often these days are hair dryers with a ceramic coating on the heating element. Coming in a variety of different configurations, ceramic-coated heating elements are said to heat more evenly and effectively. It’s also popular to infuse the ceramic with materials such as crushed tourmaline, which is said to support the creation of ions and ideal heat flow.. The majority of hair dryers seem to use a three-section heating element (low, medium and high heating element) controlled by a selector switch.

Thermostat Switch

Each heating element has special thermostat strip mounted near the air nozzle which senses the temperature of the air flow. The thermostat switch is normally closed and is open if the hot air blown outside the heated circuit becomes too hot. A fuse may be found connected in series between the temperature control switch and the heater element.

Selector switch

As the majority of hair dryers seem to use a three-section heating element(low, medium and high heating element) controlled by a selector switch, the switch will have three positions – low, medium and high to select the heating element as per the requirement. The selector switch will always be connected to the motor and then to the heater circuit so that the heating element cannot be turned on unless the motor is running.

Safety while using Hair Dryer

Safety cut-off switch – Your scalp can be burned by temperatures more than 140 degrees Fahrenheit (approximately 60 degrees Celsius) To ensure that the air coming out of the barrel never nears this temperature, hair dryers have some type of heat sensor that trips the circuit and shuts off the motor when the temperature rises too much. This hair dryer and many others rely on a simple bimetallic strip as a cut off switch.

Bimetallic strip – Made out of sheets of two metals, both expand when heated but at different rates. When the temperature rises inside the hair dryer, the strip heats up and bends because one metal sheet has grown larger than the other. When it reaches a certain point, it trips a switch that cuts off power to the hair dryer.

Thermal fuse – For further protection against overheating and catching fire, there is often a thermal fuse included in the heating element circuit. This fuse will blow and break the circuit if the temperature and current are excessively high.

Insulation – Without proper insulation, the outside of the hair dryer would become extremely hot to the touch. If you grabbed it by the barrel after using it, it might seriously burn your hand. To prevent this, hair dryers have a heat shield of insulating material that lines the plastic barrel.

Protective screens – When air is drawn into the hair dryer as the fan blades turn, other things outside the hair dryer are also pulled toward the air intake. This is why you’ll find a wire screen covering the air holes on either side of the dryer. After you’ve used a hair dryer for a while, you’ll find a large amount of lint building up on the outside of the screen. If this were to build up inside the hair dryer, it would be scorched by the heating element or might even clog the motor itself. Even with this screen in place, you’ll need to periodically pick lint off the screen. Too much lint can block the airflow into the dryer, and the hair dryer will overheat with less air carrying away the heat generated by the nichrome coil or other type of heating element. Newer hair dryers have incorporated some technology from the clothes dryer: a removable lint screen that’s easier to clean.

Front grill – The end of the barrel of a hair dryer is covered by a grill made out of material that can withstand the heat coming from the dryer. This screen makes it difficult for small children (or other especially inquisitive people) to stick their fingers or other objects down the barrel of the dryer, where they could be burned by contact with the heating element.

Troubleshooting of Hair Dryer

Problems | Causes | Solution |

Unit gives no heat at any position and/or motor does not operate | 1. Blown of fuse 2. Broken wire/loose connection in power cord or in the circuit. 3. Defective switch. 4. Open circuited temperature control/ defective thermostat. 5. Open circuted windigs. 6. Short circuited windings. | 1. Replace with proper capacity fuses. 2. Check all wiring connection and cord set for its continuity. Solder the broken wire or change the cable/power cord. 3. Check the switch for proper operation. If faulty, replace the switch. 4. Check the temperature control/ thermostat. If faulty, replace it. 5. Solder the joints of the open circuted end of the winding; if not possible, rewind. 6. Rewind. |

Unit operates intermittently | 1. Loose connections. 2. Intermittent switch operation (that is it turns one time and refuses to operate the next time) | 1. If you find any such loose connection, reconnect them. Replace the temperature control or thermostat if all connections are tight and intermittent cycling continues. 2. The easiest way to clean the swithc is to spary a cleaning liquid into the switch, work the switch several time, then recheck the switch. If it sill does nor work properly, replace it. |

Unit gives no heat at any position, but motor runs | 1. Leads of heater open. 2. Open in heater circuit | 1. Check the heater leads for porper connections. 2. Check the heater contacts on thermostat for contamination. Check the fuse link and heater element continuity. The thermostat mut be in closed position before a continuity check can be made. Allow the hair dryer to cool so that the contact could be closed. |

Motor does not run but heater operates. | 1. Defective switch. 2. Bent impeller/fan. 3. Defective thermostat. 4. Open circuited windings. 5. Improper connections | 1. Change the switch. 2. Check the beaing and fan/ impeller for bent. Lubricate the bearings, if required, with very small of light oil. 3. Check the thermostat for proper cut off. Also check the thermostat or termperature contro for continuity. 4. Solder the joints of the open circuted winding. If it is not possible, rewind. 5. See that the connections are proper as per the connection diagram. |

Appliance is noisy | 1. Improper mounting 2. Improper fitting of impeller 3. Warped impeller/ fan blade 4. Loose parts in blower compartment. | 1. Check the tightness of the motor mounting. 2. Check and fit the impeller on the shaft in proper position. 3. Check for a warped impeller or fan blade. If faulty, repace it. 4. Re-fastern them. |