Table of Contents

ToggleConstruction of SF6 circuit breaker

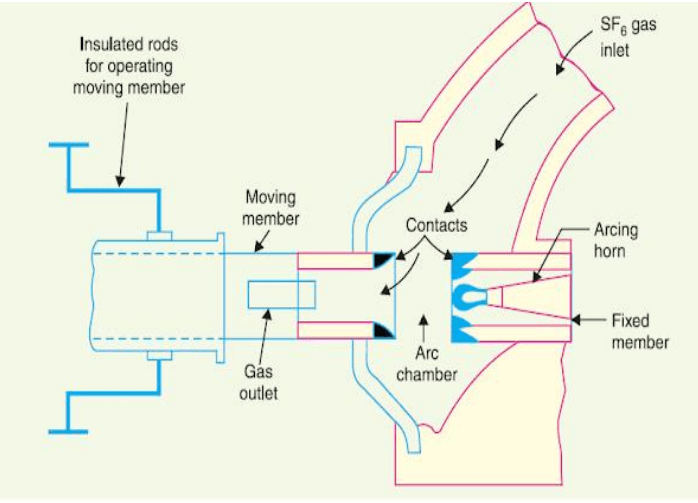

SF6 Circuit breaker consists of fixed and moving contacts enclosed in a chamber containing SF6 gas.

This chamber is connected to SF6 gas reservoir.

The fixed contact is a hollow cylindrical current carrying contact fitted with an arc horn.

Moving contact is also a hollow cylinder with rectangular holes in the sides to permit SF6 gas. To let out through the holes.

The tips of fixed contact , moving contact and arcing horn are coated with copper – tungsten arc resistant material.

Working Principle of SF6 circuit breaker

Sulphur hexaflouride gas is used as the arc quenching medium.SF6 is an electro-negative gas and has a strong tendency to absorb free electrons.

Contacts are opened in high pressure flow of SF6 gas and an arc is struck between them. Conducting free electrons in the arc are rapidly captured by the gas to form immobile negative ions.

This loss of conducting electrons in the arc quickly builds up enough insulation strength to extinguish the arc.

In the ON position of circuit breaker, the contacts remain surrounded by SF 6 gas at a pressure of about 2.8kg/cm2.

When the breaker operates, the moving contact is pulled apart, and an arc is struck between the contacts.

Movement of the moving contact is synchronized with the opening of a valve which permits SF6 gas at 14 kg/cm2 pressure from the reservoir to the arc interruption chamber.

SF6 gas rapidly absorbs the free electrons and form immobile negative ions

This causes a sudden increase in the die-electric strength of the medium and arc gets extinguished. After the arc extinction, the valve is closed y the action of a set of springs.

Advantages of SF6 circuit breaker

Due to the superior arc quenching properties of the SF6 gas, the SF6 circuit breakers have many advantages over oil or air circuit breakers.

Due to the superior arc quenching property of SF6, such circuit breakers have very short arcing time.

Since the dielectric strength of SF6 gas is 2 to 3 times that of air, such breakers can interrupt much larger currents.

The SF6 circuit breaker gives noiseless operation due to its closed gas circuit and no exhaust atmosphere, unlike the air blast circuit breaker.

The closed gas enclosure keeps the interior dry so that there is no moisture problem.

There is no risk of fire in such breakers because SF6 gas is non-inflammable.

There are no carbon deposits so that tracking and insulation problems are eliminated.

The SF6 breakers have the low maintenance cost, light foundation requirements, and minimum auxiliary equipment.

Since SF6 breakers are totally enclosed and sealed from the atmosphere, they are particularly suitable where explosion hazard exists e.g., coal mines.

Disadvantages of SF6 Circuit Breakers

SF6 breakers are costly due to the high cost of SF6.

Since SF6 gas has to be reconditioned after every operation of the breaker, additional equipment is required for this purpose.

Applications of SF6 Circuit Breakers

A typical SF6 circuit breaker consists of interrupter units each capable of dealing with currents up to 60 kA and voltages in the range of 50—80 kV. A number of units are connected in series according to the system voltage. SF6 circuit breakers have been developed for voltages 115 kV,220kV,400kV, power ratings more than 5MVA and interrupting time less than 3 cycles.

As soon as I observed this web site I went on reddit to share some of the love with them.

Pingback: Accessories used in Electrical Substation - Electricalsphere

I like gathering utile information , this post has got me even more info! .

Hi! I know this is kinda off topic but I’d figured I’d ask. Would you be interested in exchanging links or maybe guest writing a blog post or vice-versa? My site discusses a lot of the same topics as yours and I believe we could greatly benefit from each other. If you’re interested feel free to shoot me an email. I look forward to hearing from you! Superb blog by the way!

Pingback: What is Core balance current transformer (CBCT)

Hi my loved one! I wish to say that this post is awesome, great written and come with almost all important

infos. I would like to see more posts like this .

Feel free to visit my page – Nordvpn Coupons Inspiresensation

hi,

thanks for appreciation. Now, my focus on spread my website content to more readers. I can not think about earning like guest post or affiliate post.

To boost my moral, Please share my website to your friends and subscribe my Insta/Telegram/Whatsapp group.

Pingback: Tripping of 220kV Feeder on SF6 lockout declaration in GIS Substation - Electricalsphere

Pingback: Switch onto Fault (SOTF) Logic - Electricalsphere

Great post, you have pointed out some good details , I besides conceive this s a very good website.

Quality analysis