What is Eddy Current?

If a coil is wound on a ferromagnetic core (such as in a transformer) and alternating current is passed through the coil, an alternating flux is set up in the core. The alternating flux induces an e.m.f. e in the coil given by e D N d,/dt However, in addition to the desirable effect of inducing an e.m.f. in the coil, the alternating flux induces undesirable voltages in the iron core. These induced e.m.f.s set up circulating currents in the core, known as eddy currents.

Since the core possesses resistance, the eddy currents heat the core, and this represents wasted energy. Eddy currents can be reduced by laminating the core, i.e., splitting it into thin sheets with very thin layers of insulating material inserted between each pair of the laminations (this may be achieved by simply varnishing one side of the lamination or by placing paper between each lamination). The insulation presents a high resistance and this reduces any induced circulating currents.

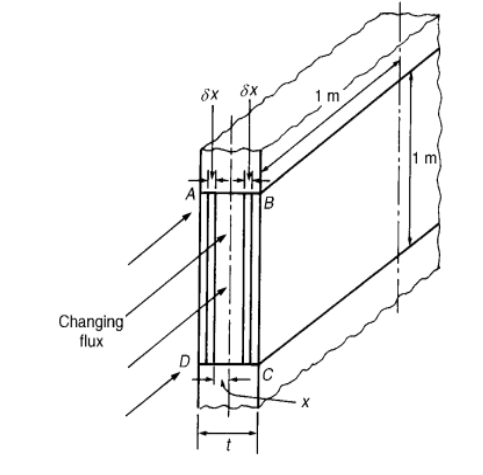

The eddy current loss may be determined as follows. Let Figure represent one strip of the core, having a thickness of t metres, and consider just a rectangular prism of the strip having dimensions tm*1m*1m as shown. The area of the front face ABCD is( t*1) m2 and, since the flux enters this face at right angles, the eddy currents will flow along paths parallel to the long sides.

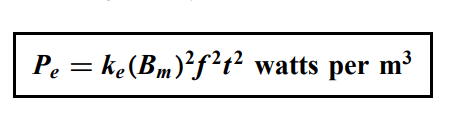

From equation, it is seen that eddy current loss is proportional to the square of the thickness of the core strip. It is therefore desirable to make lamination strips as thin as possible. However, at high frequencies where it is not practicable to make very thin laminations, core losses may be reduced by using ferrite cores or dust cores. Ferrite is a ceramic material having magnetic properties similar to silicon steel, and dust cores consist of fine particles of carbonyl iron or permalloy (i.e. nickel and iron), each particle of which is insulated from its neighbour by a binding material. Such materials have a very high value of resistivity.

Excellent beat ! I wish to apprentice even as you amend your web site, how can i subscribe for a blog website? The account aided me a acceptable deal. I were a little bit acquainted of this your broadcast offered vibrant transparent idea

Pingback: Hot spot formation in Transformer - Electricalsphere

Pretty component of content. I simply stumbled upon your web site and in accession capital to assert that I get actually loved account your blog posts. Any way I will be subscribing in your augment and even I fulfillment you get entry to constantly fast.

hello there and thank you for your information – I have certainly picked up something new from proper here. I did however expertise a few technical points the usage of this website, as I experienced to reload the website lots of times prior to I could get it to load properly. I had been thinking about in case your hosting is OK? Not that I’m complaining, but sluggish loading cases times will sometimes affect your placement in google and can damage your high quality ranking if ads and ***********|advertising|advertising|advertising and *********** with Adwords. Well I am including this RSS to my e-mail and can glance out for a lot extra of your respective interesting content. Ensure that you replace this once more soon..

I’ve been surfing online more than three hours today, yet I never found any interesting article like yours. It’s pretty worth enough for me. In my opinion, if all webmasters and bloggers made good content as you did, the internet will be much more useful than ever before.

Great – I should definitely pronounce, impressed with your site. I had no trouble navigating through all the tabs as well as related info ended up being truly simple to do to access. I recently found what I hoped for before you know it in the least. Quite unusual. Is likely to appreciate it for those who add forums or anything, web site theme . a tones way for your client to communicate. Excellent task..

Really enjoyed this blog post, is there any way I can get an update sent in an email whenever you write a fresh article?

Hi there, just become alert to your weblog through Google, and found that it’s really informative. I am gonna be careful for brussels. I’ll be grateful when you continue this in future. A lot of folks might be benefited out of your writing. Cheers!

I cherished up to you will obtain performed proper here. The comic strip is attractive, your authored material stylish. nevertheless, you command get bought an impatience over that you would like be handing over the following. in poor health unquestionably come further in the past once more as exactly the similar just about a lot regularly within case you shield this increase.

great points altogether, you simply gained a new reader. What would you suggest about your post that you made a few days ago? Any positive?

Great write-up, I¦m regular visitor of one¦s web site, maintain up the nice operate, and It’s going to be a regular visitor for a long time.

Valuable info. Lucky me I found your website by accident, and I’m shocked why this accident did not happened earlier! I bookmarked it.

You completed some nice points there. I did a search on the topic and found a good number of folks will consent with your blog.

I am usually to running a blog and i actually respect your content. The article has really peaks my interest. I am going to bookmark your web site and keep checking for brand spanking new information.

Thanks for appreciation

I haven’t checked in here for a while as I thought it was getting boring, but the last few posts are good quality so I guess I will add you back to my everyday bloglist. You deserve it my friend 🙂

Thanks for appreciation.

Share to your social group.

Keep working ,fantastic job!

Very detailed