Table of Contents

ToggleWhat is Motor Growler test?

A simple and most common method to test armature winding for short and open coils is by a growler. There are two types of growlers. 1) Internal growlers 2) External growlers.

An external growler is used for testing small armatures and an internal growler for large DC armatures and AC motor stator windings.

External growler

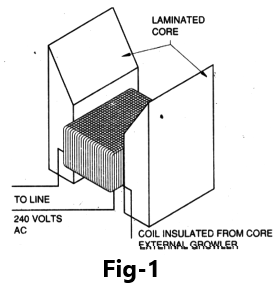

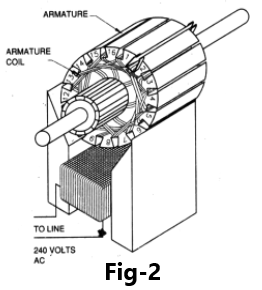

An external growler shown in Fig-1 is an electromagnetic device that is used to detect and locate grounded, shorted and open coils in an armature. This growler consists of a coil wound around an iron core and is connected to a 240 volt AC line. The core is generally H shaped and cut out on to so that the armature will fit on it, as shown in Fig-2.

When an alternating current is applied to the growler coil, the voltage will be induced in the armature coils by transformer action.

Internal growler

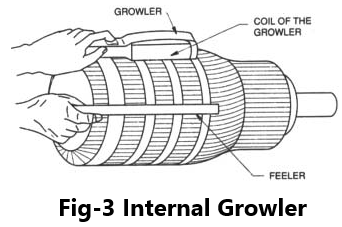

An internal growler, such as the one used for stators, may be used for armatures as well. These are made with or without built-in feelers.The growler with a built-in feeler has a flexible blade attached to the growler so that a hacksaw blade or similar instrument is not necessary. This type is especially desirable in smaller stators that have no room for a separate feeler. Fig-3 shows an internal growler with a separate feeler, used for large armatures.

Growler test for grounded coil

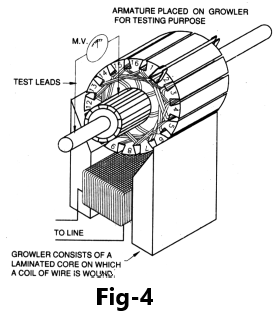

The armature to be tested is placed on the growler and then the growler is switched ‘ON’. Place one lead of an AC milli-voltmeter on the to commutator bar the other meter lead on the shaft, as shown in Fig-4.

If a reading is noticed on the meter, turn the armature so that the armature so that the next commutator bar is in same position as the earlier one, and test as before. Continue in this manner until all the bars are tested. Where the meter gives no deflection, it is an indication that the grounded coil is connected to this particular bar.

Growler test for shorted coil

The procedure to test for short circuits in an armature as follows.

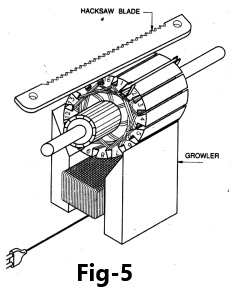

The armature to be tested is placed on the growler and then the growler is switched on. A thin piece of metal, such as a hacksaw blade, is held over to the slot of the armature as shown in Fig-5.

In case of short in the winding, the blade will vibrate rapidly and create a growling noise. If the blade remains stationary, it is an induction that no short exists in the coil under test. After several to slots have been given the hacksaw blade test, turn the armature so that the few slots are on to. Test as before and continue this procedure for the entire armature.

An armature having cross connections or equalizers cannot be given the hacksaw blade test. This type of armature will cause the blade to vibrate at every slot, which would seem to indicate that possibly every coil is shorted.

Growler test for an open coil

Growlers are also provided with meters (milli-volt or ammeter) on the panel with variable resistance. In this case an open in the armature coil can be found out as follows.

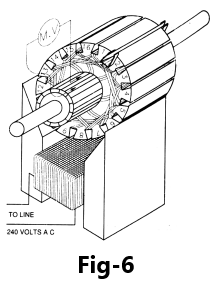

To locate an open coil with a growler, set up the armature on the growler on the growler in the usual manner. Test the top two adjacent bars with an AC millivoltmeter as shown in Fig-6.

Rotate the armature and continue testing the adjacent bars. When the millivoltmeter bridges the two bars connected to the open coil, the meter pointer will not deflect. All the other bars will give a deflection. This test for an open coil can be made without the meter by shorting the two tops bars with a piece of wire.

Absence of a spark indicates that the coil is open. The open may be either at the commutator bar or in the coil itself. The procedure may be used to determine the location of the loads of a shorted coil. However, the hacksaw blade test is the most satisfactory method of determining a shorted coil.