High Rupturing Capacity (HRC) fuses play a vital role in electrical systems, ensuring safety and preventing catastrophic failures. In this comprehensive guide, we will delve into the intricacies of HRC fuses, exploring about HRC fuse: their working, Application and future technology.

Table of Contents

ToggleIntroduction

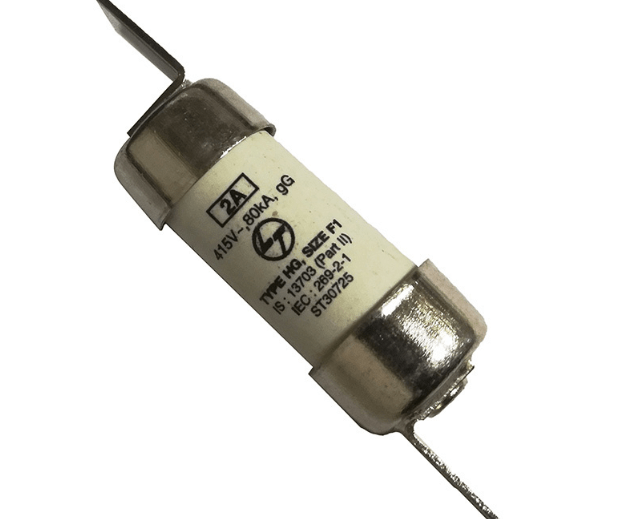

HRC fuse is an electrical safety device that operated to provide over current protection of electrical circuit. HRC fuse is one kind of fuse wire, which carries short circuit current in set of period. If fault occurs in electrical circuit, than heavy fault current flows from HRC fuse. Due to heavy fault current flow from fuse, it blows off. HRC fuse is made with glass or some other kind of chemical compound.

With a heavy load capacities of the distribution network extremely heavy currents would flow into the fault and the fuse clearing the fault would be required to withstand heavy stress in the process. H.R.C cartridge fuses are therefore used for such duties and these are specially designed for extremely rapid operation.

HRC fuses are also designed to absorb rapid heat produced by are formed at the time of blowing out. The rating is much more accurate and are particularly suited for breaking much heavier currents safely.

Construction

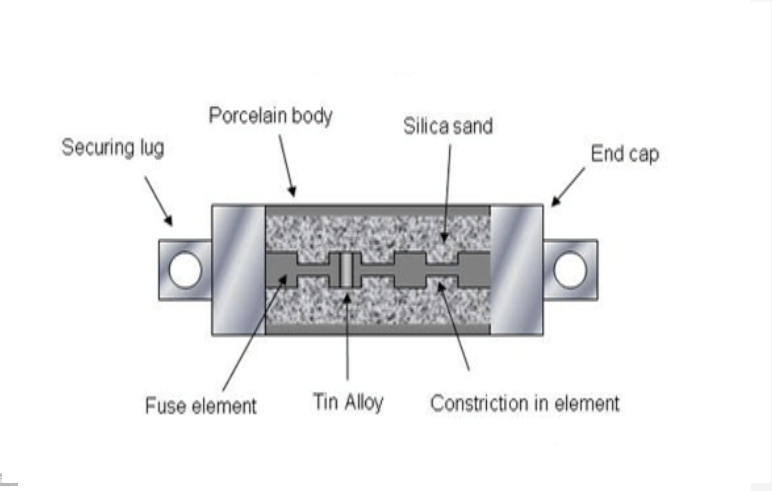

An HRC Fuse consists of a highly heat-resistant material (such as ceramic) body with metal end caps, which are welded to a silver current-carrying element. The internal space of the fuse body is completely filled with a powder. The material used to fill the inner space may include plaster of Paris, quartz, chalk, marble, dust, and cooling mediums, among others. This filling prevents overheating, allowing the fuse to carry normal current.

The heat produced vaporizes the silver element. A chemical reaction occurs between the silver vapor and the filling powder, resulting in a high-resistance substance. This substance helps quench the arc in the fuse. When the load capacity is very high the level of fault current will also increase. So faulty clearing device will be under heavy stress.

HRC fuse is preferred for heavy duty and rapid operation. It consists of heat resisting ceramic cylindrical body having low co-efficient of thermal expansion.The fuse element is made up of silver or silver alloy to improve fuse life. It is filled with incombustible powder which absorbs the arc produced at the time of blowing.

Working Principle

The working principle of an HRC fuse involves a fuse element made of materials with high melting points, such as silver or silver alloys. When a fault current surpasses the designated level, the fuse element melts, opening the circuit and preventing further damage. The high melting point ensures that the fuse can withstand normal operating currents while providing reliable protection during overcurrent events.

Applications of HRC Fuses

HRC fuses find application in various sectors due to their ability to safeguard electrical systems. Here are some key areas where these fuses are commonly employed:

- Industrial Sector:

In industrial settings, where heavy machinery and high-power equipment are prevalent, HRC fuses are essential for preventing electrical faults and ensuring uninterrupted operations. They are often used in conjunction with motor control centers and distribution boards.

- Power Distribution:

HRC fuses play a critical role in power distribution networks. They are strategically placed at key points in the grid to protect transformers, switchgear, and other vital components from overcurrent situations that could lead to equipment damage or even fires.

- Renewable Energy Systems:

With the increasing focus on renewable energy sources, HRC fuses are integral in protecting solar inverters, wind turbine generators, and other components within renewable energy systems. This ensures the reliability and longevity of these systems.

- Residential Applications:

In homes, HRC fuses are commonly used in distribution boards to protect household appliances and wiring from overcurrent conditions. They contribute to the overall safety of residential electrical systems.

Advantages of HRC fuse

The rating is much more accurate. It is widely used because of silent operation and non-deteriorating characteristics.

maintenance free and easy to install.

Speed of operation is very high.

Maintenance cost is practically is zero.

High breaking capability

They provide reliable operation.

They cheaper than other protecting devices.

Disadvantages of HRC fuse

It can not reused after fail

It causes overheating

Due to overheating, it damages near by contact and switches.

Types of HRC fuse

NH type: NH type fuse provides short circuit and overload protection for low and medium voltage. They provide backup protection to motor starters and other device against short circuit and overload. They are available in light and compact dimension.

Blade type: Blade Type HRC fuse is also known as spade or plug-in fuses. It comes in plastic body and two metal caps arrange in socket. They are used in car for protection from short circuit.

Din type: These are available in broad range of rated current for used in different fields for different reason including their features and different temperature States. This types of fuses are available for different voltages level and can be used in transformer protection and backup protection. This type of fuse are use in air and mining gas insulator switch gear transformer and feeder sectionalise protection.

Future Technological Trends

As technology continues to advance, several trends are emerging in the field of electrical protection, including HRC fuses. Here are some potential future developments:

- Smart HRC Fuses:

Integration of smart technologies into HRC fuses is a plausible future trend. Smart fuses could offer real-time monitoring of electrical parameters, enabling predictive maintenance and enhancing overall system reliability.

- Electric Vehicles (EVs):

HRC fuses can be employed in the battery management system of electric vehicles. They provide protection against overcurrent conditions, such as short circuits or excessive charging/discharging currents, which could potentially damage the battery pack

- Nanotechnology Enhancements:

Nanotechnology holds promise for improving the performance of HRC fuses. Nano-sized materials may enhance the fuse’s response time and efficiency, providing faster and more precise protection against overcurrent events.

- Increased Integration with IoT:

The Internet of Things (IoT) can play a significant role in the evolution of HRC fuses. Integration with IoT platforms could enable remote monitoring, diagnostics, and control, contributing to more efficient and adaptive electrical protection.

Please show video on "About HRC fuse: their working, Application and future technology"

Frequently Asked Question(FAQ)

1.What is full form of HRC fuse?

HRC fuse full form is High Rupturing Capacity (HRC) fuses.

2.What is HRC fuse?

HRC fuse is an electrical safety device that operated to provide over current protection of electrical circuit. HRC fuse is one kind of fuse wire, which carries short circuit current in set of period.

3.How to replace HRC fuse?

Before replace HRC fuse, it’s confirm to power turn off.Then remove blown fuse and insert new same rating fuse. It’s important to follow safety rules and the manufacturer’s guidelines and recommendations when replacing fuses.

- How to check HRC fuse is fail?

By using multi-meter, you will check Continuity of HRC fuse. If Continuity not shown in meter then HRC fuse is fail.

- what is rating of HRC fuse?

A HRC fuse rating is the current need to blow (break) the fuse. When a fuse has blown it removes electrical power from an electrical circuit. The fuse rating is usually on the side of the fuse. Thefuse rating is usually defined in ‘amps’.

6.How do you select HRC fuse?

Selection of HRC fuse base on maximum operational voltage, rated breaking capacity, rated current, breaking range, utilisation category.

- Can I use AC rated HRC fuse in DC application?

There are fuses with equal AC and DC voltage ratings but in most cases, the DC voltage rating is significantly less than the AC voltage rating. If a fuse only has an AC voltage rating, it most probably was not designed for DC applications and hence has never been tested within a DC environment.

- Can I replace HRC fuse with circuit breaker?

In some cases, YES you can replace it with a circuit breaker. However,due to their unique qualities, HRC fuse are still required upstream in the critical role. They are, in essence, the ‘gatekeepers’ of the protection system. They are actually the most important protective device in the system.

Pingback: What is MCB? It’s future technology - Electricalsphere

Pingback: Importance of Earthing in electrical system - Electricalsphere

Pingback: Different types of Protection on Transmission line

Pingback: ELCB: Working principle, Full name and Circuit diagram - Electricalsphere

Pingback: DC distribution in 132 KV, 220 KV, 400 KV Control and Relay Panel in substation

Pingback: What is Switchgear in Electrical Engineering - Electricalsphere

Pingback: What is Drop Out (swing out) Fuse

Pingback: Types of Fuse - Electricalsphere