Table of Contents

ToggleTypes of Circuit Breaker

The CBs are of six types:

- Oil circuit breaker

- Air circuit breaker

- SF6 circuit breaker

- Vacuum circuit breaker

- Water circuit breaker

- Miniature circuit breaker

Phenomenon of arc formation in circuit breaker

When a fault occurs a heavy current flows through the contact of the CB. When these contact separate, the resistance increases and large fault current produces excessive heat. This heat ionised the air or the oil and as a result an arc is produced between the contact of the CB. There are two method which can be used extinguish this arc .

- By increasing resistance of the arc: This method is used in DC circuit breakers. In this method, the current is reduced to such a value that it cannot maintain the arc. This is done by increasing resistance of the arc either by separating the contents sufficiently or by splitting the arc through use of conducting pieces between the contacts.

- By zero current method: This method is used to extinguish arc in a.c. Circuit breakers. The current become zero after every half cycle and at that instant the arc is extinguished of its own. Efforts are made at this instant to prevent the arc from restricting for the next cycle.

Oil circuit breaker(OCB)

A high-voltage circuit breaker in which the arc is drawn in oil to dissipate the heat and extinguish the arc; the intense heat of the arc decomposes the oil, generating a gas whose high pressure produces a flow of fresh fluid through the arc that furnishes the necessary insulation to prevent a restrike of the arc.

Plane (bulk) OCB: Bulk oil circuit breaker is such types of circuit breakers where oil is used as arc quenching media as well as insulating media between current carrying contacts and earthed parts of the breaker.

Self blast OCB: In this type of circuit breaker, the gases produced during arcing are confined to a small volume by the use of an insulating rigid pressure chamber or pot surrounding the contacts. Since the space available for the arc gases is restricted by the chamber, a very high pressure is developed to force the oil and gas through or around the arc to extinguish it.

Minimum oil circuit breaker(MOCB)

In the bulk oil circuit breakers discussed so far, the oil has to perform two functions. Firstly, it acts as an arc quenching medium and secondly, it insulates the live parts from earth.It has been found that only a small percentage of oil is actually used for arc extinction while the major part is utilised for insulation purposes.

For this reason, the quantity of oil in bulk oil circuit breakers reaches a very high figure as the system voltage increases. This not only increases the expenses, tank size and weight of the breaker but it also increases the fire risk and maintenance problems.

Construction minimum oil circuit breaker(MOCB)

There are two compartments separated from each other but both filled with oil. The upper chamber is the circuit breaking chamber while the lower one is the supporting chamber. The two chambers are separated by a partition and oil from one chamber is prevented from mixing with the other chamber.

This arrangement permits two advantages. Firstly, the circuit breaking chamber requires a small volume of oil which is just enough for arc extinction. Secondly, the amount of oil to be replaced is reduced as the oil in the supporting chamber does not get contaminated by the arc.

Operation and arc quenching OF MOCB

Under normal operating conditions, the moving contact remains engaged with the upper fixed contact. When a fault occurs, the moving contact is pulled down by the tripping springs and an arc is struck. The arc energy vaporises the oil and produces gases under high pressure.

This action constrains the oil to pass through a central hole in the moving contact and results in forcing series of oil through the respective passages of the turbulator. The process of turbulation is orderly one, in which the sections of the arc are successively quenched by the effect of separate streams of oil moving across each section in turn and bearing away its gases.

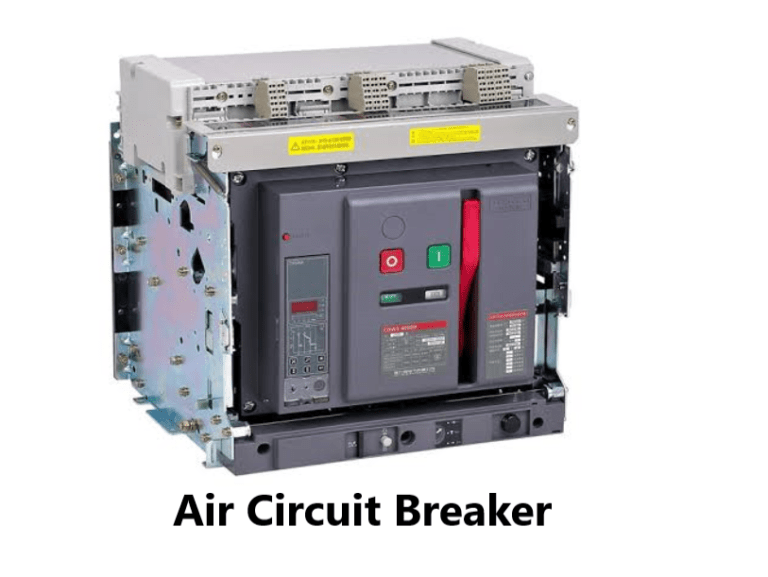

Air Circuit Breaker (ACB)

This type of circuit breakers, is those kind of circuit breaker which operates in air at atmospheric pressure. After development of oil circuit breaker, the medium voltage air circuit breaker (ACB) is replaced completely by oil circuit breaker in different countries. But in countries like France and Italy, ACBs are still preferable choice up to voltage 15 KV. It is also good choice to avoid the risk of oil fire, in case of oil circuit breaker.

Cross blast air circuit breaker

In these ACBs the air blast is at right angle to the arc. The moving contact of this ACB has a number of spring loaded fingers and the moving contact is of plat blades. The contacts are made of silver tungsten alloys. When a fault occurs an air blast thrown away at right angle to the arc. The arc splitters quench the arc quickly.

Axial blast for air circuit breaker

In axial blast ACB the moving contact is in contact with fixed contact with the help of a spring pressure as shown in the figure. There is a nozzle orifice in the fixed contact which is blocked by tip of the moving contact at normal closed condition of the breaker.

When fault occurs, the high pressure air is introduced into the arcing chamber. The air pressure will counter the spring pressure and deforms the spring hence the moving contact is withdrawn from the fixed contact and nozzle hole becomes open.

At the same time the high pressure air starts flowing along the arc through the fixed contact nozzle orifice. This axial flow of air along the arc through the nozzle orifice will make the arc lengthen and colder hence arc voltage become much higher than system voltage that means system voltage is insufficient to sustain the arc consequently the arc is quenched.

SF6 Circuit Breaker

Sulphur hexafluoride circuit breakers protect electrical power stations and distribution systems by interrupting electric currents, when tripped by a protective relay. Instead of oil, air, or a vacuum, a sulphur hexafluoride circuit breaker uses sulphur hexafluoride (SF6 ) gas to cool and quench the arc on opening a circuit.

Advantages over other media include lower operating noise and no emission of hot gases, and relatively low maintenance. Developed in the 1950s and onward, SF6 circuit breakers are widely used in electrical grids at transmission voltages up to 800 kV, as generator circuit breakers, and in distribution systems at voltages up to 35 kV.

Construction of SF6 Circuit Breaker

A sulphur hexafluoride (SF6) circuit breaker consists of fixed and moving contacts enclosed in a chamber. The chamber is called arc interruption chamber which contains the sulphur hexafluoride (SF6) gas. This chamber is connected to sulphur hexafluoride (SF6) gas reservoir.

A valve mechanism is there to permit the gas to the arc interruption chamber. When the contacts of breaker are opened, the valve mechanism permits a high-pressure sulphur hexafluoride (SF6) gas from the reservoir to flow towards the arc interruption chamber.

The fixed contact is a hollow cylindrical current carrying contact fitted with an arcing horn. The moving contact is also a hollow cylinder with rectangular holes in the sides. The holes permit the sulphur hexafluoride gas (SF6) gas to let out through them after flowing along and across the arc.

The tips of fixed contact, moving contact and arcing horn are coated with a copper-tungsten arc-resistant material. Since sulphur hexafluoride gas (SF6) gas is costly, it is reconditioned and reclaimed using the suitable auxiliary system after each operation of the breaker.

Working of SF6 Circuit Breaker

In the closed position of the breaker, the contacts remain surrounded by sulphur hexafluoride gas (SF6) gas at a pressure of about 2.8 kg/cm2.

Different company manufacturing breaker have different SF6 gas pressure in circuit breaker.

When the breaker operates, the moving contact is pulled apart and an arc is struck between the contacts. The movement of the moving contact is synchronised with the opening of a valve which permits sulphur hexafluoride gas (SF6) gas at 14 kg/cm2 pressure from the reservoir to the arc interruption chamber.

The high-pressure flow of sulphur hexafluoride gas (SF6) rapidly absorbs the free electrons in the arc path to form immobile negative ions which are ineffective as charge carriers.

The result is that the medium between the contacts quickly builds up high dielectric strength and causes the extinction of the arc. After the breaker operation (i.e. after arc extinction), the valve is closed by the action of a set of springs.

Vacuum circuit breaker (VCB)

A vacuum circuit breaker is a kind of circuit breaker where the arc quenching takes place in vacuum medium. The operation of switching on and closing of current carrying contacts and interrelated arc interruption takes place in a vacuum chamber in the breaker which is called vacuum interrupter.

Construction of Vacuum circuit breaker

The vacuum circuit breaker comprises a steel arc chamber in the center-symmetrically arranged ceramic insulators.

The material used for current carrying contacts plays an important role in the performance of the vacuum circuit breaker. The alloys like, Copper-bismuth or copper-chrome are the ideal material to make VCB contacts.

the Vacuum circuit breaker consists of a fixed contact, a moving contact and a vacuum interrupter. The moving contact is connected to the control mechanism by stainless steel bellow. The arc shields are supported o the insulating housing such that they cover on these shields and is prevented from condensing on the insulating enclosure.

The possibility of a leak is eliminated due to permanent sealing of vacuum chamber for that a glass vessel or ceramic vessel is used as the outer insulating body.

Working of Vacuum circuit breaker

when the contacts are separated due to some abnormal conditions, an arc is struck between the contacts, the arc is produced due to ionization of metal ions and depends very much on the material of contacts.

The arc interruption in vacuum interrupters is different from other types of circuit breakers. The separation of contacts causes the release of vapor which is filled in the contact space. It consists positive ions liberated from contact material. The vapor density depends on the current in the arc.

When the current decreases, the rate of vapor release decreases and after current zero, the medium regain its dielectric strength if the vapor density is reduced.

When current to be interrupted is very small in a vacuum, the arc has several parallel paths. The total current is divided into many parallel arcs which repel each other and spread over the contact surface. This is called diffused arc which can be interrupted easily.

At high values of current, the arc gets concentrated in a small region. It causes rapid vaporization of the contact surface. The interruption of the arc is possible if arc remains in diffused state. If it is quickly removed from the contact surface, the arc will be re-strike.

Arc extinction in vacuum breakers is greatly influenced by material and shape of the contacts and the technique of considering metal vapor. The path of the arc is kept moving so that temperature at any one point will not be high.

After the final arc interruption, there is rapidly building up of dielectric strength which is peculiar of the vacuum breaker. They are suitable for capacitor switching as it will give a re-strick free performance. The small current is interrupted before natural current zero, which may cause chopping whose level depends on the material of contact.

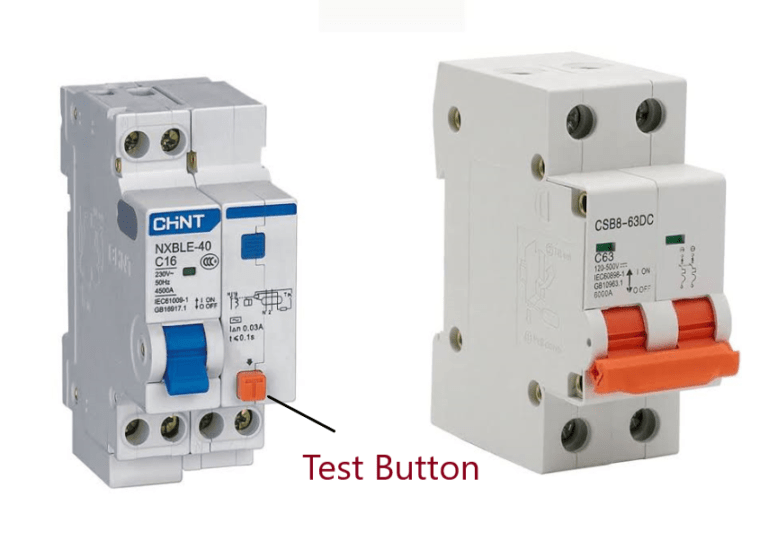

Miniature circuit breaker (MCB)

An MCB or miniature circuit breaker is an electromagnetic device that embodies complete enclosure in a molded insulating material. The main function of an MCB is to switch the circuit, i.e., to open the circuit (which has been connected to it) automatically when the current passing through it (MCB) exceeds the value for which it is set. It can be manually switched ON and OFF as similar to normal switch if necessary.

MCBs are of time delay tripping devices, to which the magnitude of overcurrent controls the operating time. This means, these get operated whenever overload exist long enough to create a danger to the circuit being protected.

Therefore, MCBs doesn’t respond to transient loads such as switches surges and motor starting currents. Generally, these are designed to operate at less than 2.5 milliseconds during short circuit faults and 2 seconds to 2 minutes in case of overloads (depending on the level of current).

Construction of MCB

An MCB embodies complete enclosure in a moulded insulating material. This provides mechanically strong and insulated housing. The switching system consists of a fixed and a moving contact to which incoming and outgoing wires are connected. The metal or current carrying parts are made up of electrolytic copper or silver alloy depending on the rating of the circuit breaker.

As the contacts are separated in the event of an overload or short circuit situation, an electric arc is formed. All modern MCBs are designed to handle arc interruption process where arc energy extraction and its cooling are provided by metallic arc splitter plates.

These plates are held in a proper position by an insulating material. Also, arc runner is provided to force the arc that is produced between the main contacts.The operating mechanism consists of both magnetic tripping and thermal tripping arrangements.

Working of MCB

Under normal working conditions, MCB operates as a switch (manual one) to make the circuit ON or OFF. Under overload or short circuit condition, it automatically operates or trips so that current interruption takes place in the load circuit.

The visual indication of this trip can be observed by automatic movement of the operating knob to OFF position. This automatic operation MCB can be obtained in two ways as we have seen in MCB construction; those are magnetic tripping and thermal tripping. Under overload condition, the current through the bimetal causes to raise the temperature of it.

The heat generated within the bimetal itself enough to cause deflection due to thermal expansion of metals. This deflection further releases the trip latch and hence contacts get separated. In some MCBs, magnetic field generated by the coil causes develop pull on bimetal such that it deflection activates the tripping mechanism.

Pingback: Types of Circuit Breaker testing and SF6 breaker testing

Pingback: DC distribution in 132 KV, 220 KV, 400 KV Control and Relay Panel in substation

Pingback: Circuit Breaker working principle and Methods of arc extinction

Pingback: MCCB circuit Breaker and their application - Electricalsphere

Pingback: What is Power System and Structure of Power system

Pingback: Air Circuit Breaker: Working, Operation and their advantages - Electricalsphere

Pingback: Minimum Oil Circuit Breaker or MOCB - Electricalsphere

Pingback: Types of Generator Protection

Pingback: What is Switchgear in Electrical Engineering

Pingback: Auto Reclose Protection in EHV Transmission Line - Electricalsphere